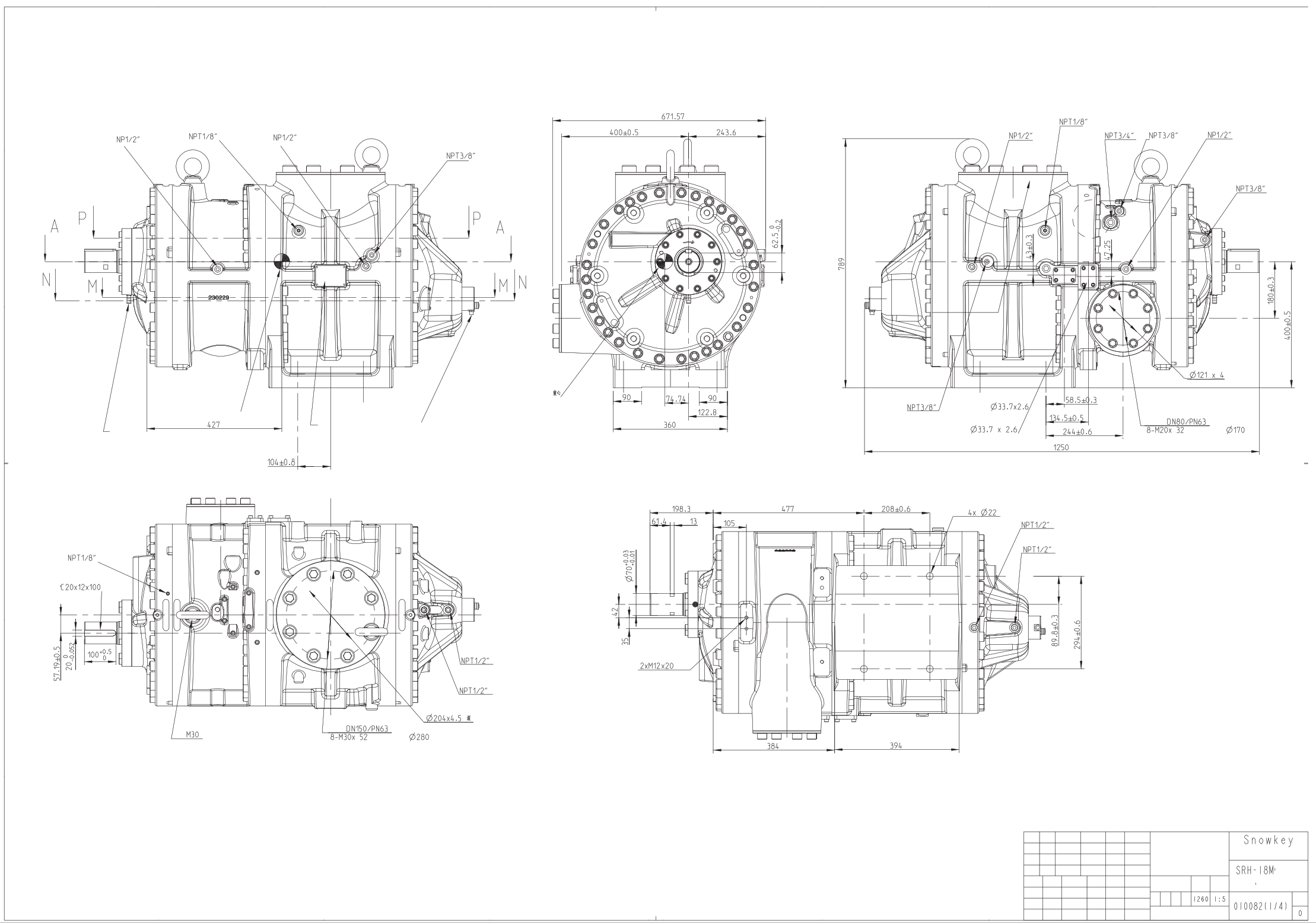

NO.SRH-18

SRH-18

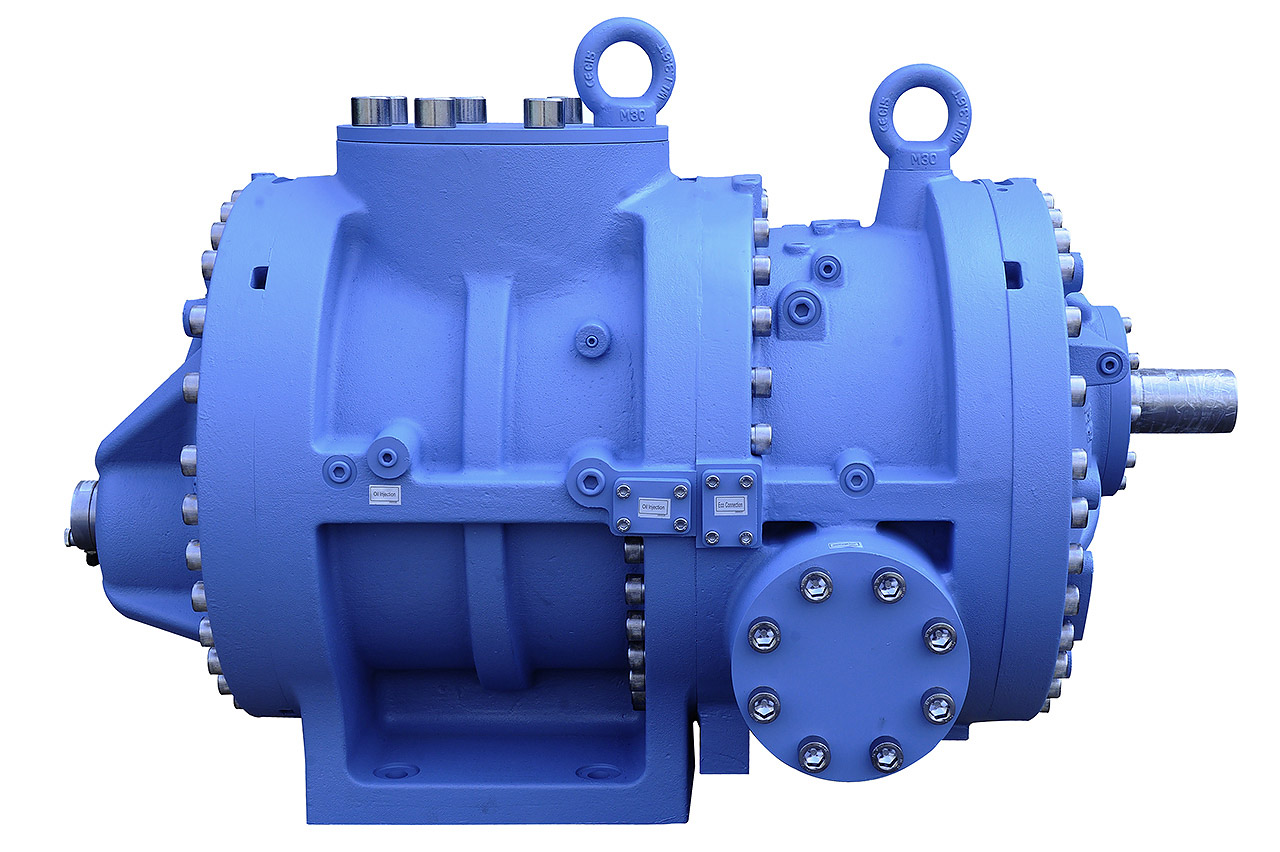

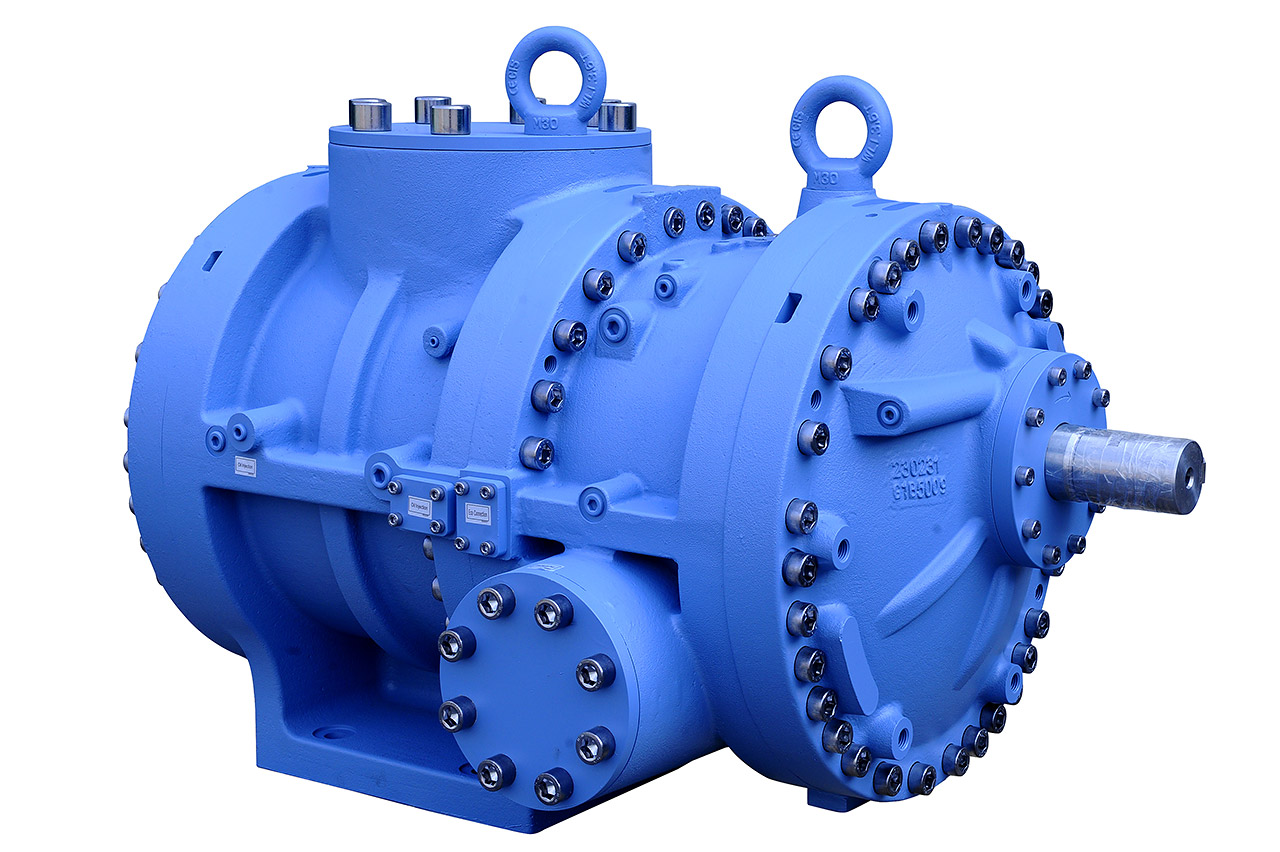

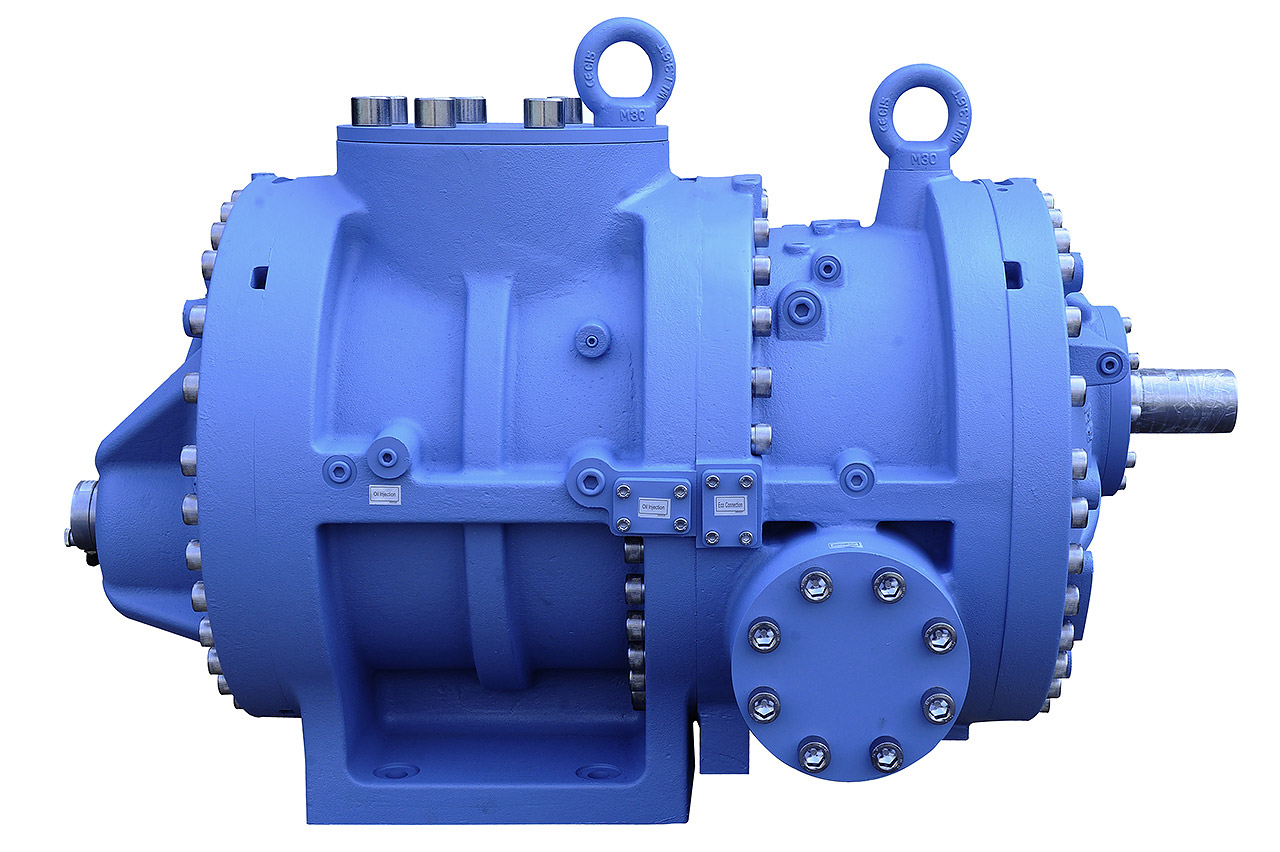

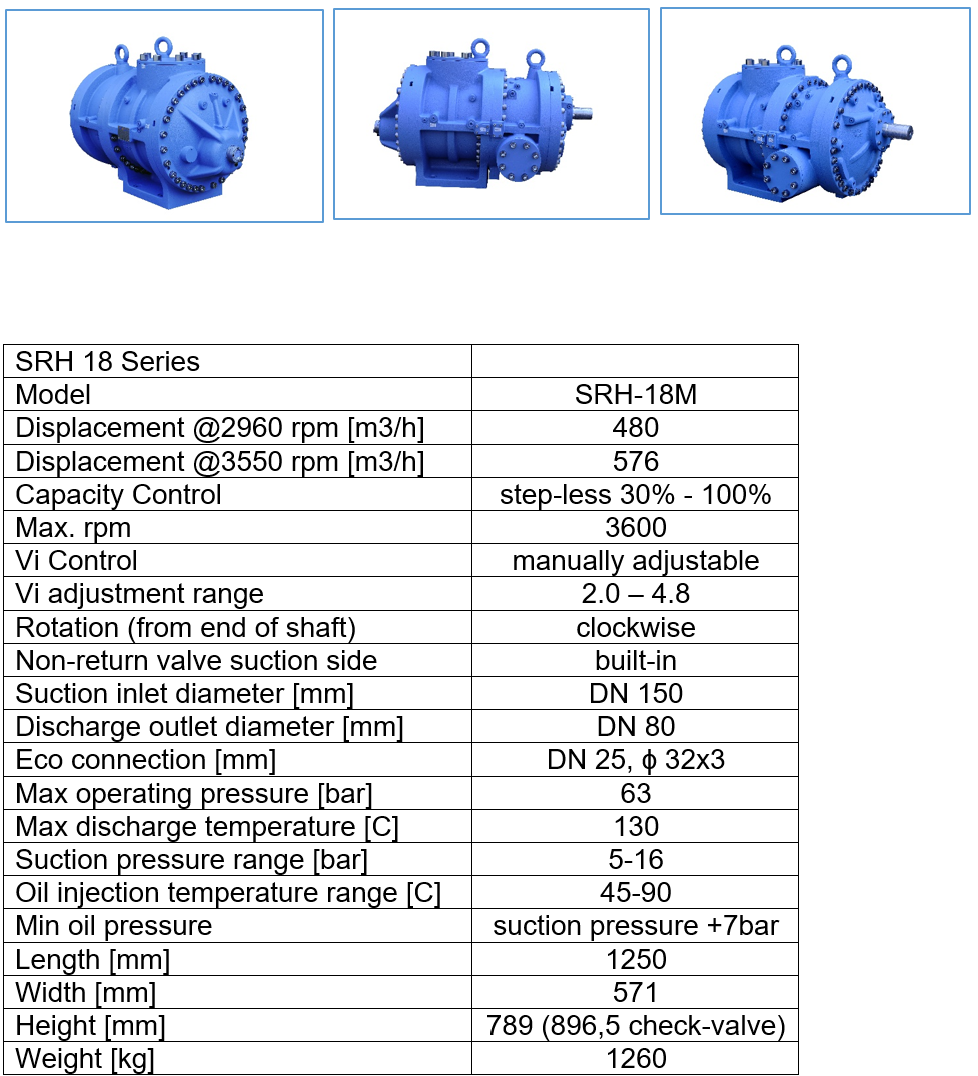

Open-type Single-stage High-pressure Screw Compressor

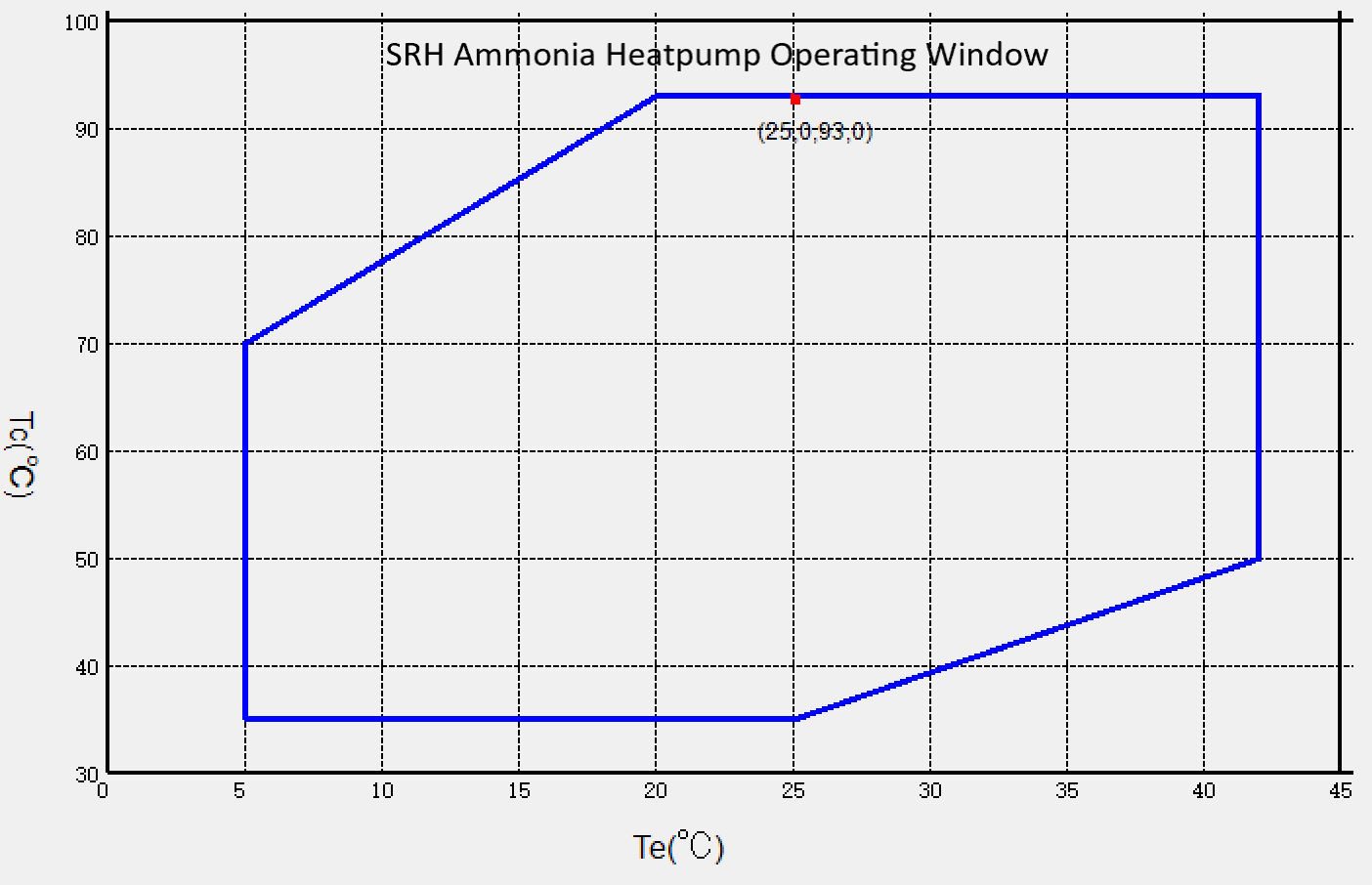

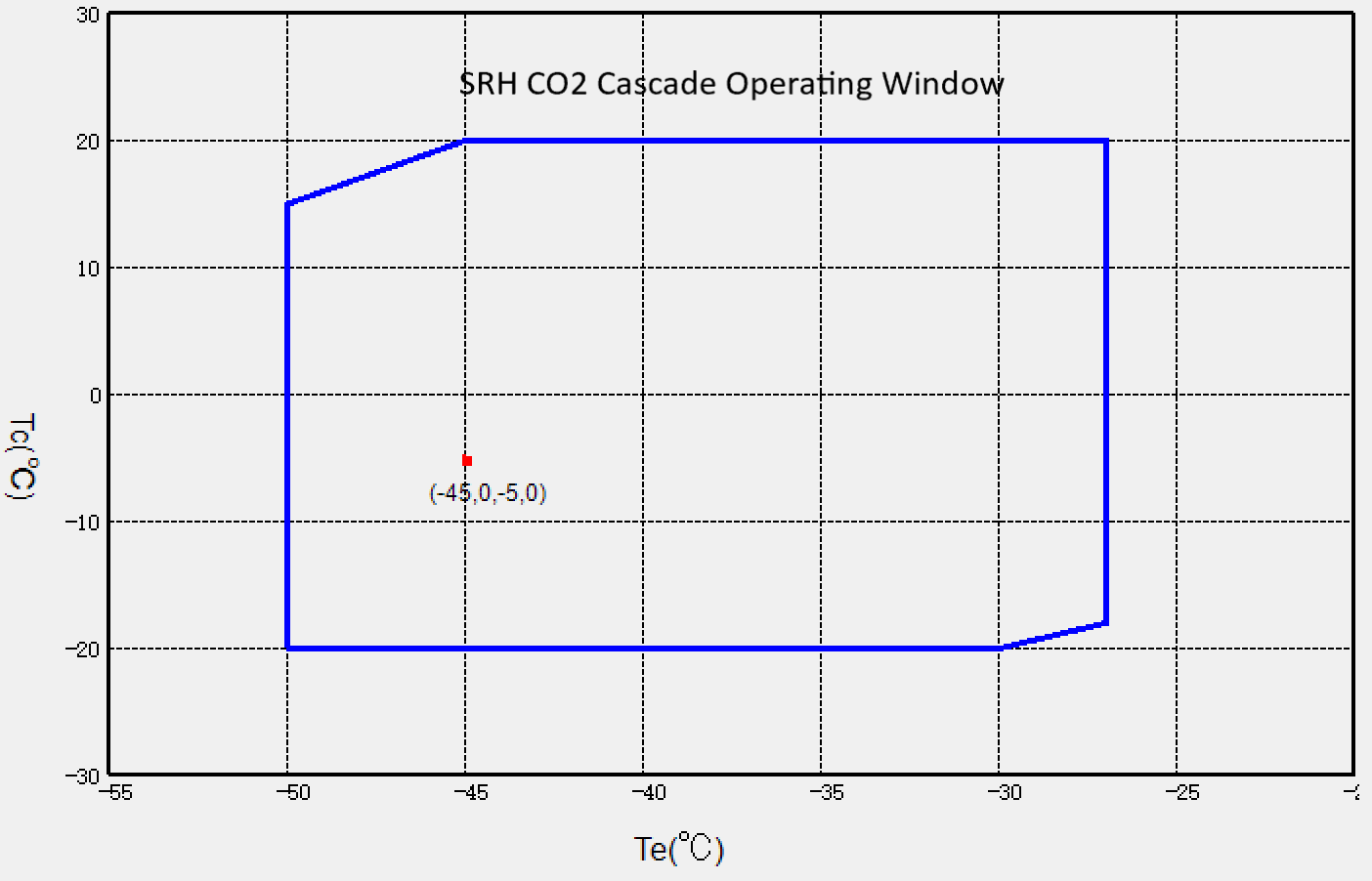

SRH open-type single-stage high-pressure Screw Compressors include 5 models with a displacement of 161- 1409 m3/h @ 2960 rpm. The large application window is optimized for two applications:

- CO2 Cascade Systems

- Ammonia Heatpumps

Rotor speed of up to 3600 rpm allow the use of frequency inverters. Togheter with step-less (30%-100%) mechanical capacity control and adjustable Vi this ensures high efficient operation and adaptation to varying load and temperature sources, thus guaranteeing high SEER values.

Features of SRH open-type single-stage high-pressure screw compressor:

- “I”type patented profile, strong lobe ratio of 4+6, high efficiency.

- Rotor is made of high-quality forged steel with micron- machining accuracy, high strength, high wear resistance, and long durability.

- The housing is made of high- strength ductile iron, design pressure: 6.3Mpa.

- Innovative shaft seal. The wear- resistant sealing surface is made of silicon carbide for high reliability.

- High- precision and wear- resistant roller/glide bearings designed for a life span of 100.000 operating hours.

- The internal compression ratio Vi can be adjusted to the existing operating conditions either manually or automatically for highest efficiency, even under varying conditions.

- Stepless capacity control (30-100%) by a mechanical slider.

- Integrated oil channels for secure lubrication of all critical spots within the compressor.

Therme Straubing is operated by the city utility provider of Straubing since 16 years as a district heating service. The heat source is thermal ground water of 36°C from which 7 K energy is extracted by the evaporating refrigerant to feed the heating loop of 70°C. Until now the system was driven by an industrial piston compressor set which has reached the end of its operational lifespan. As replacement industrial screw compressors have been chosen due to their reliability and serviceability.

Technical data:

Heating capacity QH: 1200 kW

Evaporation To: 26° C

Condensing Tc: 72° C

Installation: 11 / 2016

![]()

Vall company is one of the largest agricultural companies in Spain.To operate their Meat Processing and Cold Storage Facility in an energy efficient and environmental benign way, they decided to employ a CO2/Ammonia Cascade system. Main technical driver is the compact construction of the compressor systems and the versatile use of CO2 for several temperature levels and small pipe diameters within their cold storage facility. This enabled to operate with very small refrigerant charges.

Technical data:

Evaporation To: -50°C/-28°C/-10°C

Condensing of CO2 Tc: -10° C

Condensing of Ammonia: +35°C

Installation: 02 / 2020