COMPRESSORS

SRM-Series

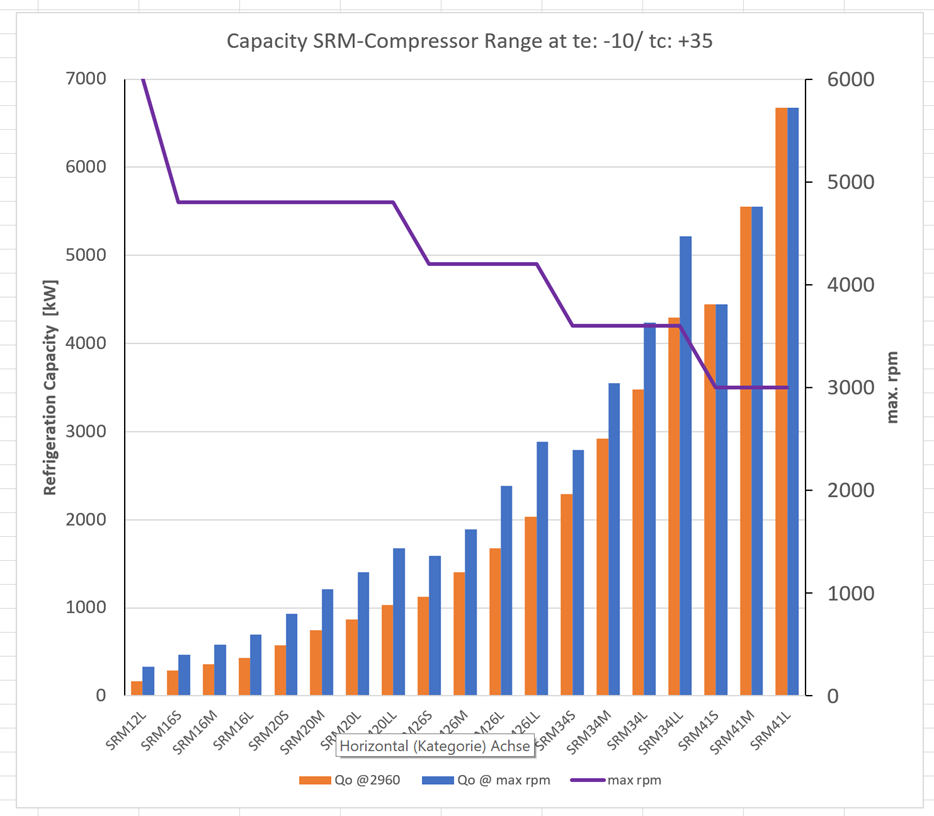

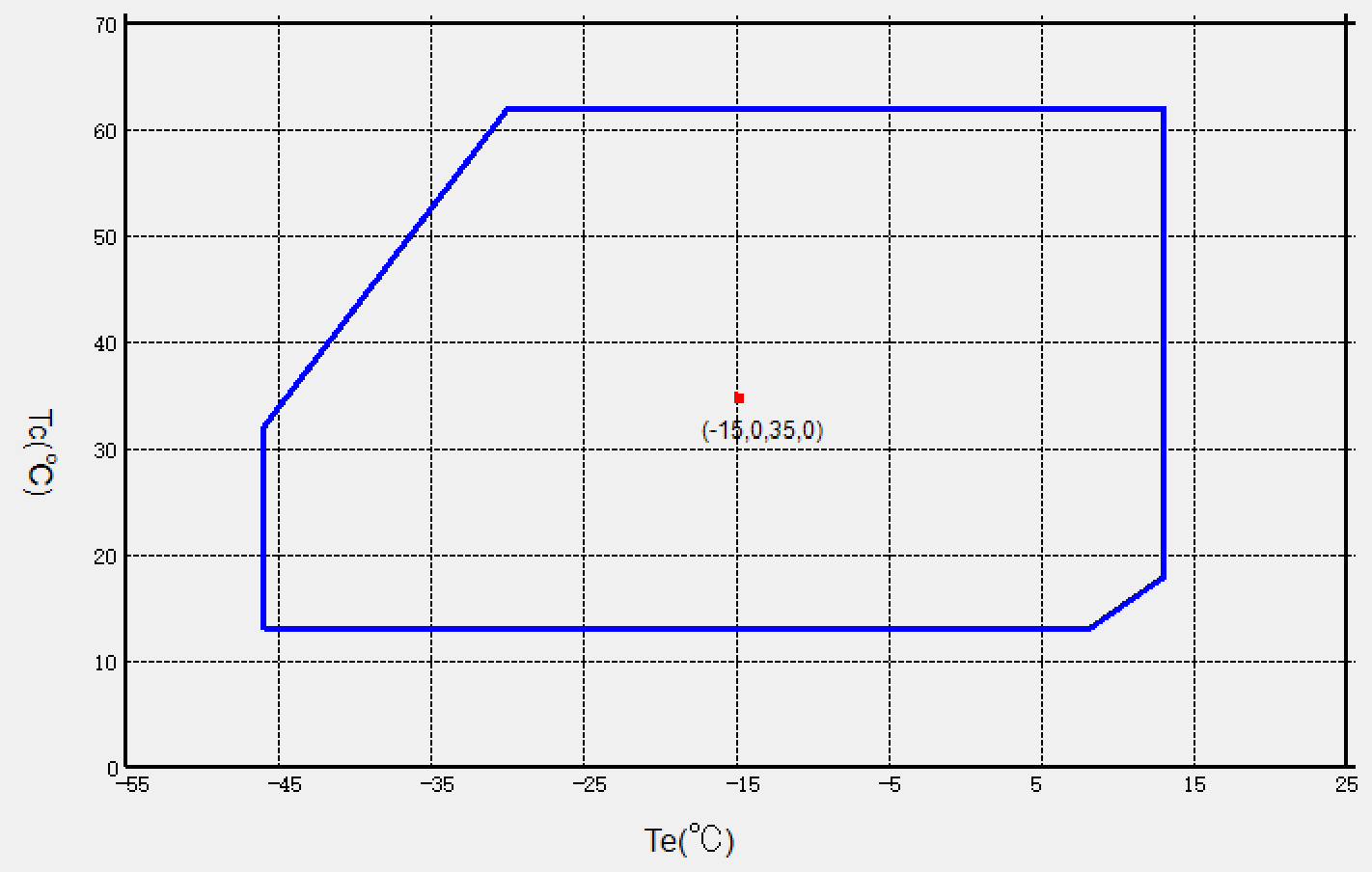

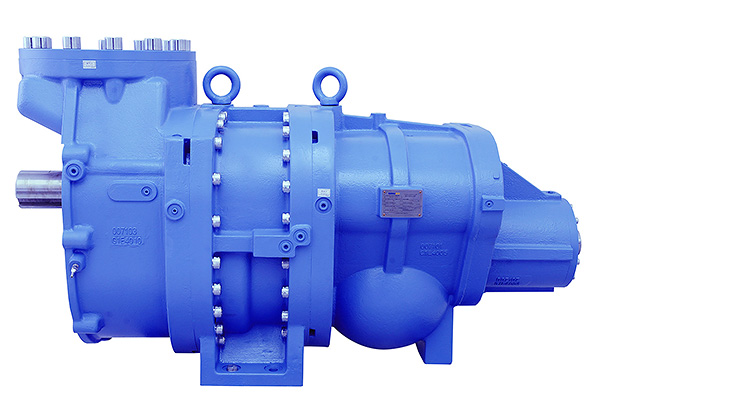

The open-drive SRM screw compressor remains the reliable workhorse for its versatility and robustness. Upgraded by the new i-profile rotors with 5/7 lobes and further improved by extra-strong bearings the SRM Series still is the benchmark of industrial refrigeration.

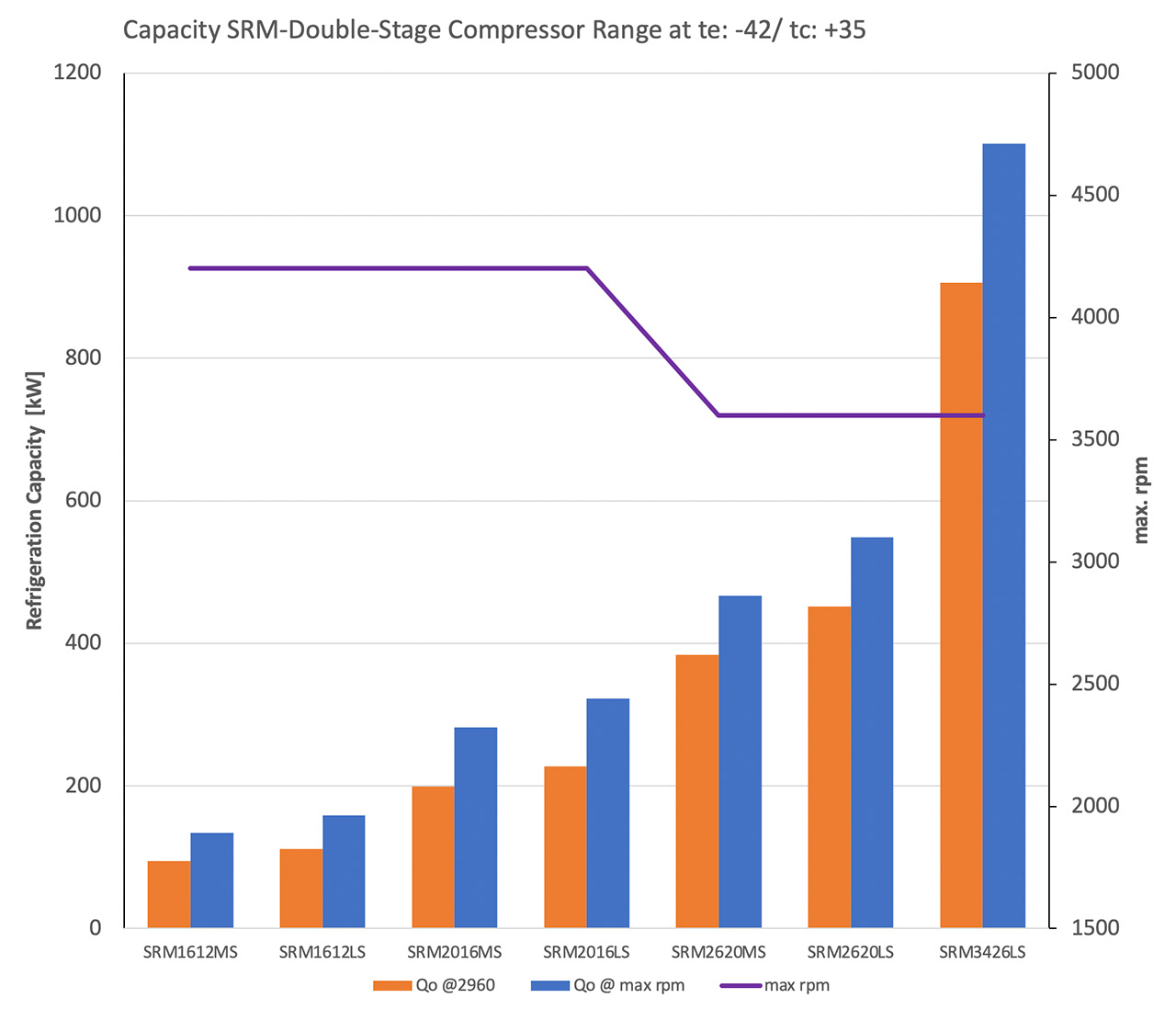

For low temperature applications where no side-load on the high stage is needed, like a dedicated package to a spiral freezer, the double stage SRM compressor offers a high efficient solution with lowest footprint compared to a booster system with two packages.

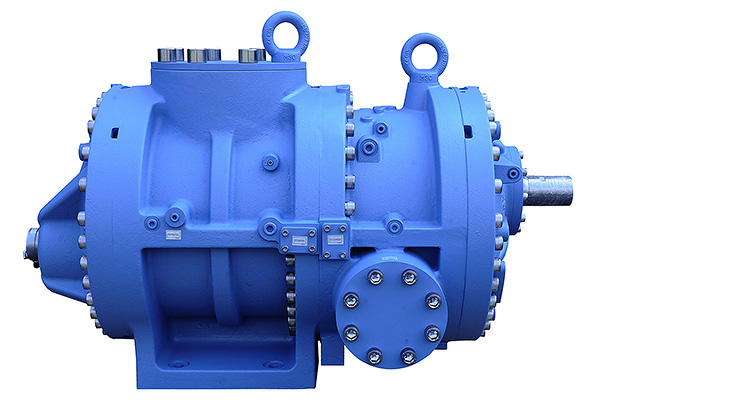

SRH-Series

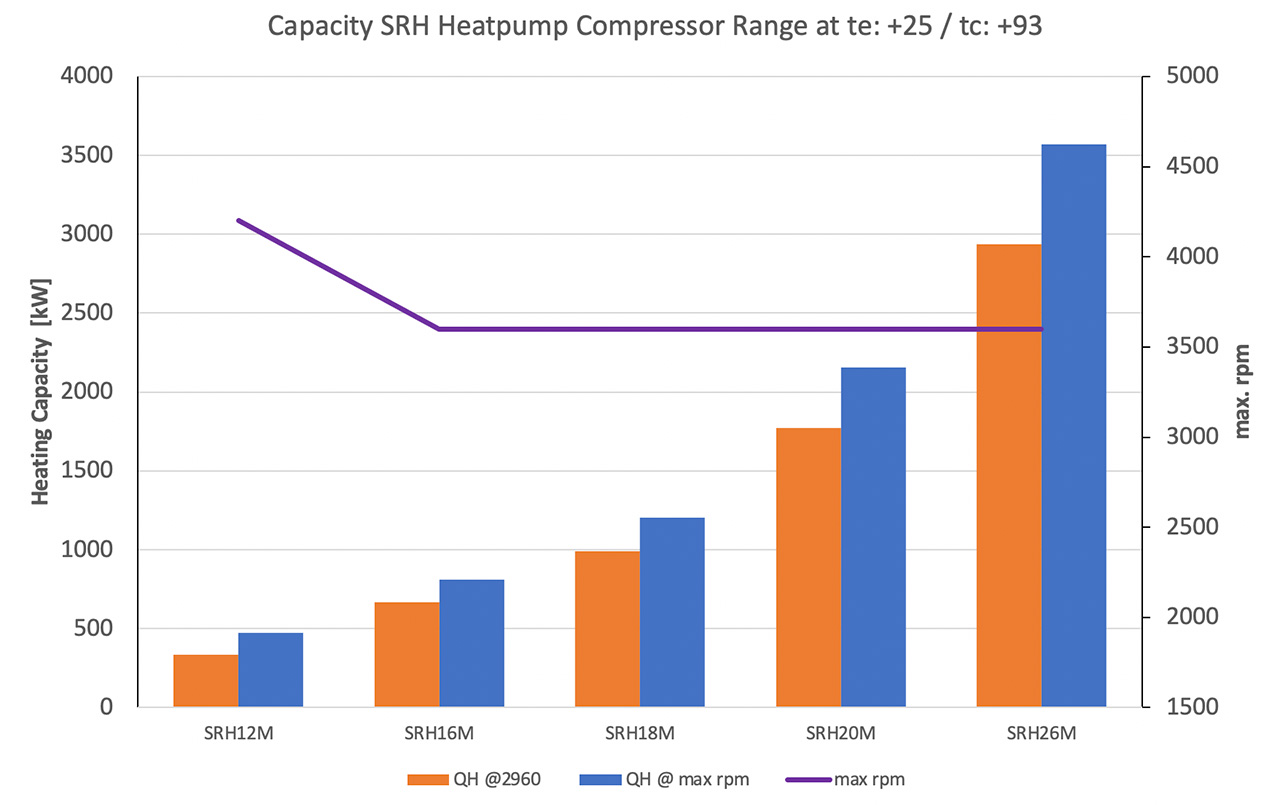

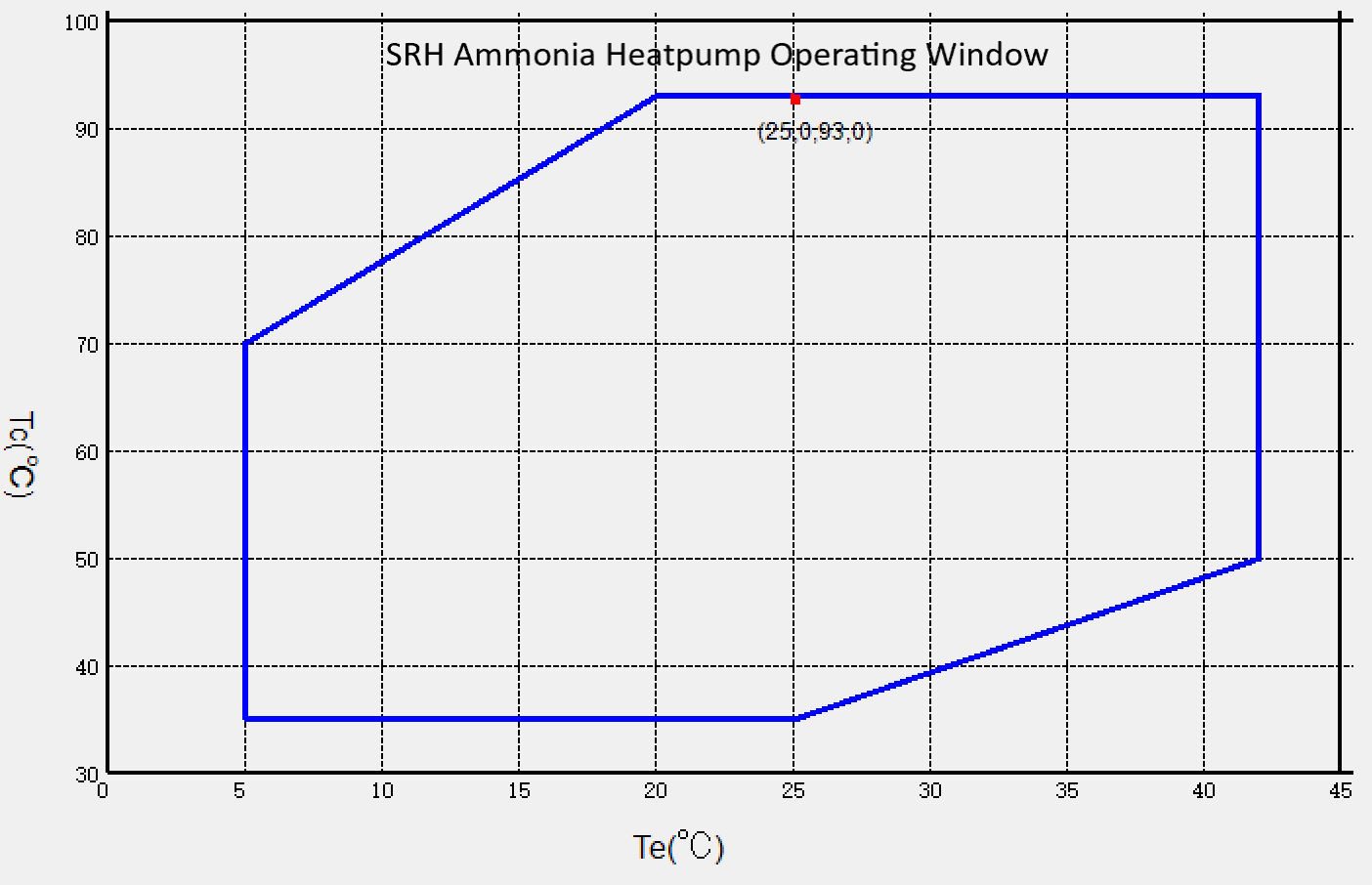

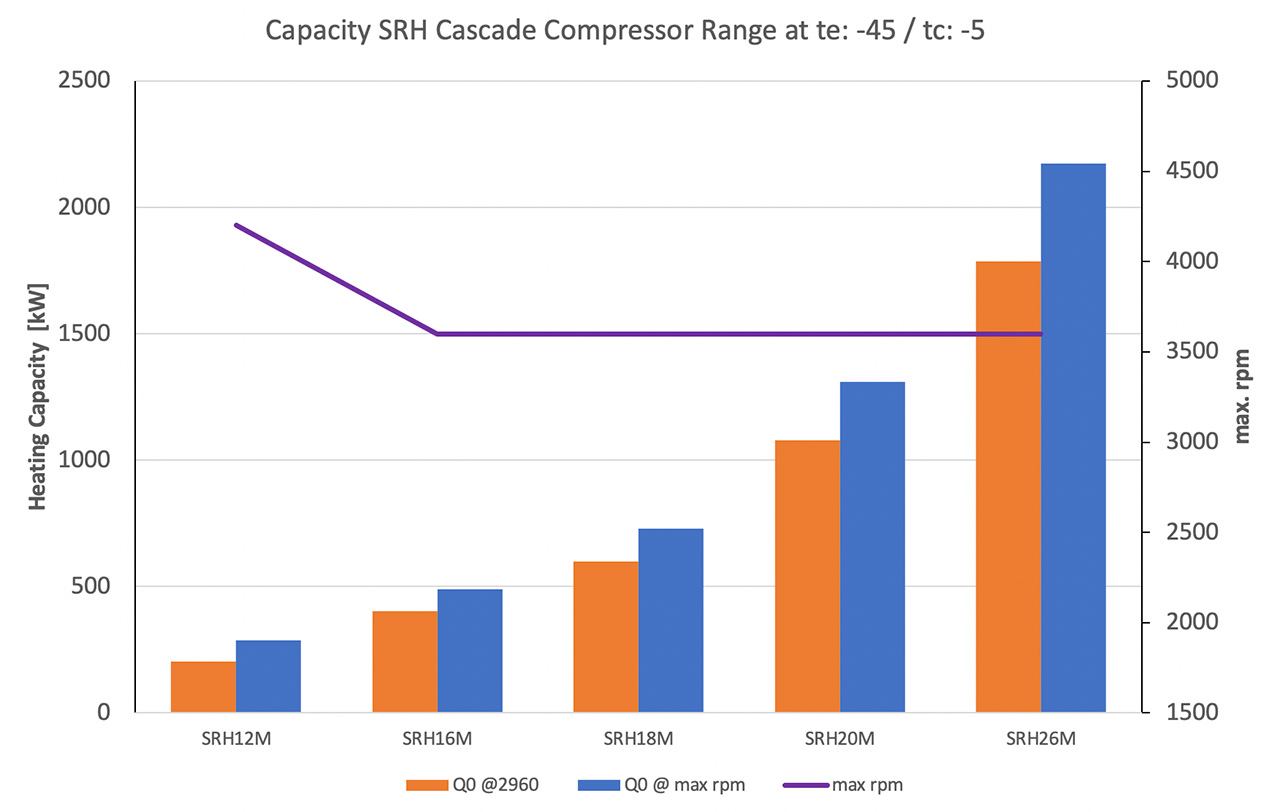

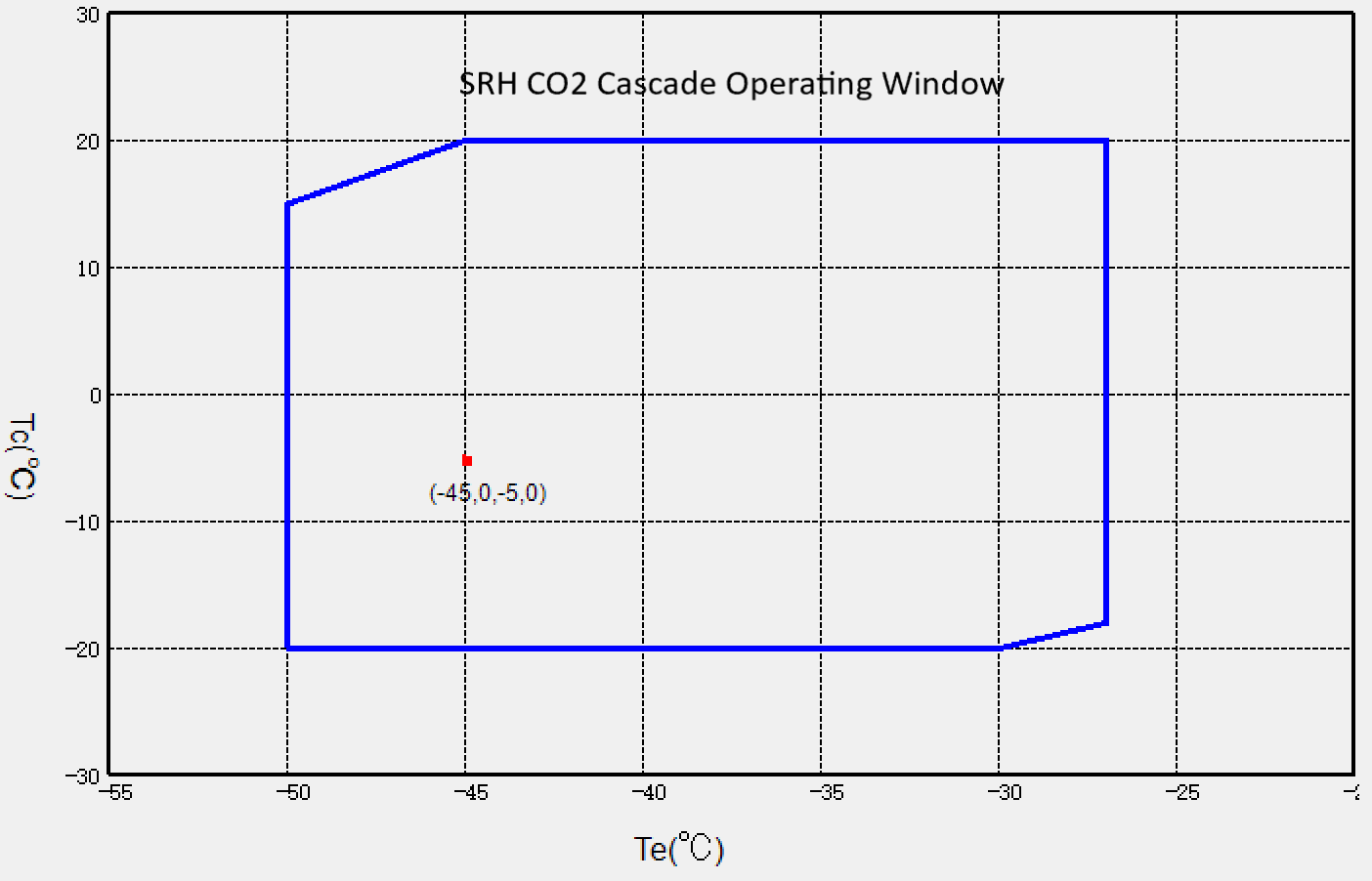

The tough brother of the SRM compressor sets the pressure benchmark to 63 bar. Thanks to glide bearings and a 4/6 lobe ratio with stronger rotor diameter this compressor range is perfectly suited to operate Ammonia Heatpumps and CO2 cascade systems with their demanding conditions.

With displacements from 161 to 1409 m3/h these compressors are capable to operate heat pumps dependent on the heat source of more than 3 MW and CO2 low temperature cascade systems of approx. 2 MW.

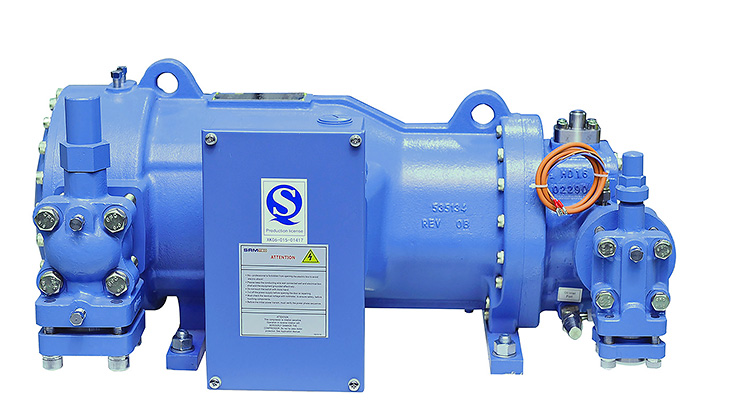

SRS-Series

Again SRMTec is writing history by the introduction of the semi-hermetic screw compressor suitable for Ammonia supporting the conversion from environment harming substances like CFC’s to Natural Refrigerants. Equipped with the i-profile and a permanent magnet motor this compressors makes no compromises on energy efficiency. The aluminium windings of the motor take no chances of deterioration compared to insulated copper windings. Without shaft-seal this technically permanent leak-proof solution is perfectly suited for applications in or close to residential areas where apprehension against Ammonia might prevail. That makes this compressor predestined for commercial process cooling or comfort cooling/heating.

The semi-hermetic Ammonia compressors offer the solution for smaller capacity ranges or where a technical permanent leak-proof system is the choice.

SRS Semi-hermetic Compressor Brochure

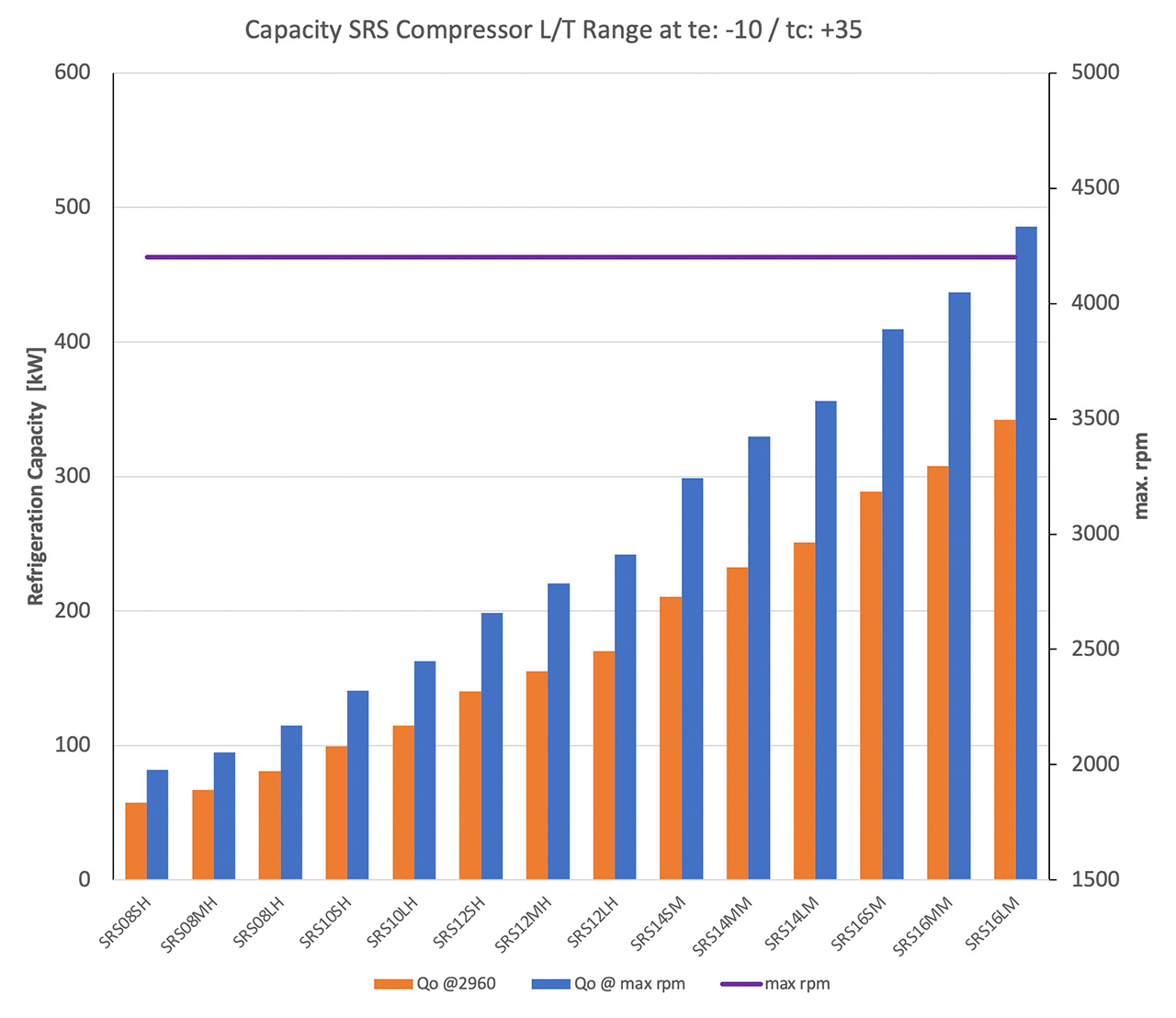

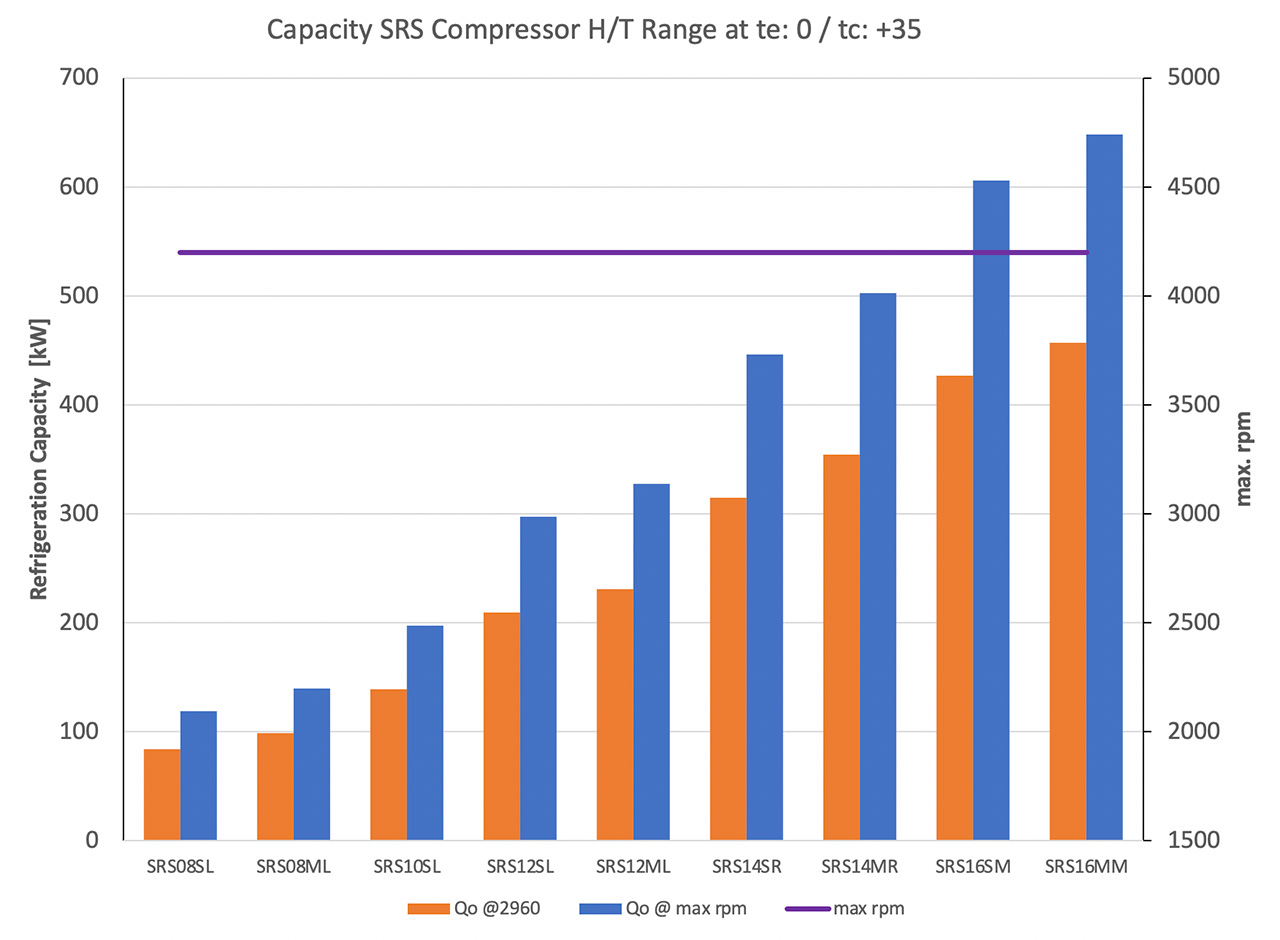

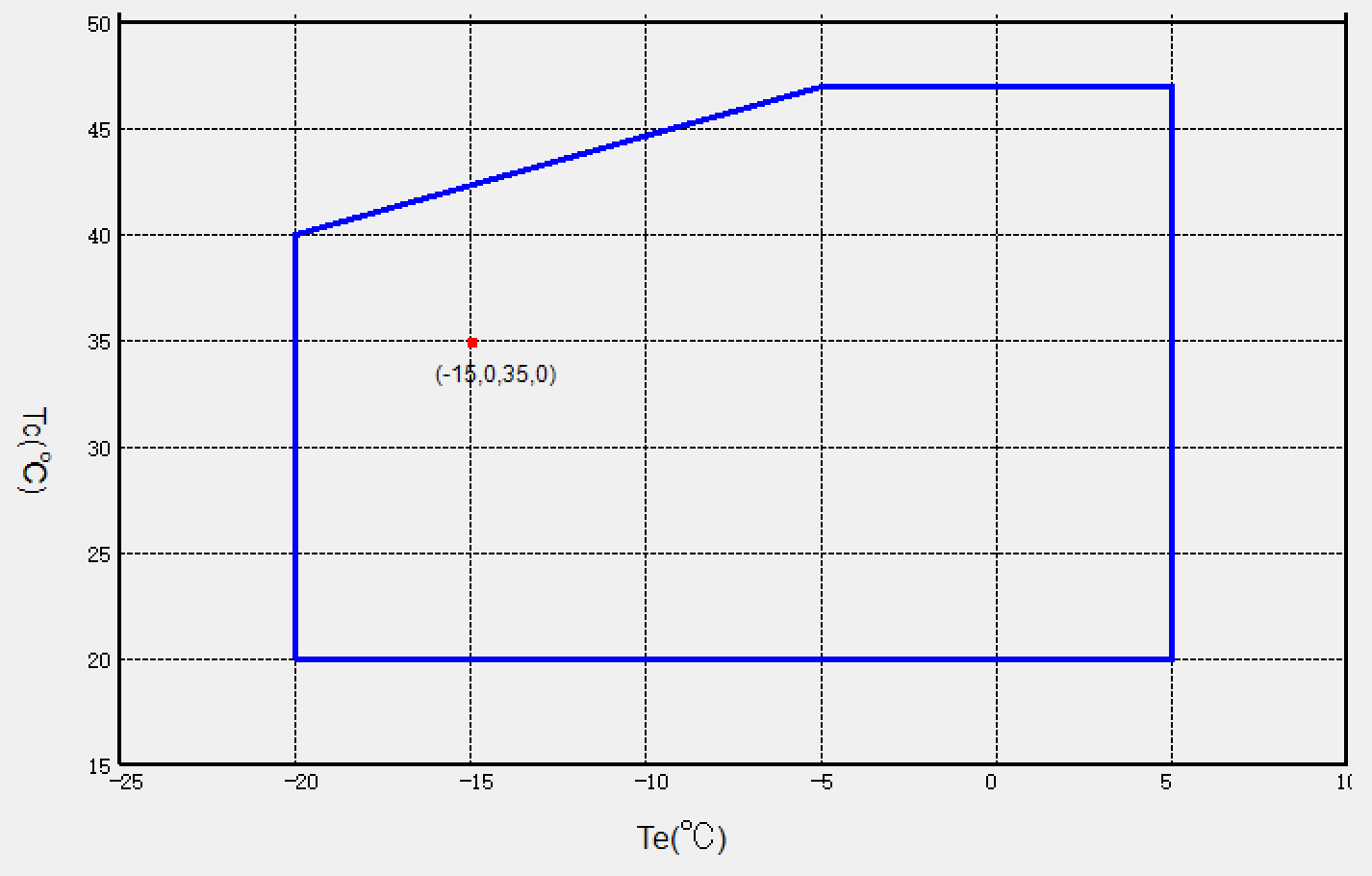

The standard application for low temperature offers small footprint and a wide capacity range.

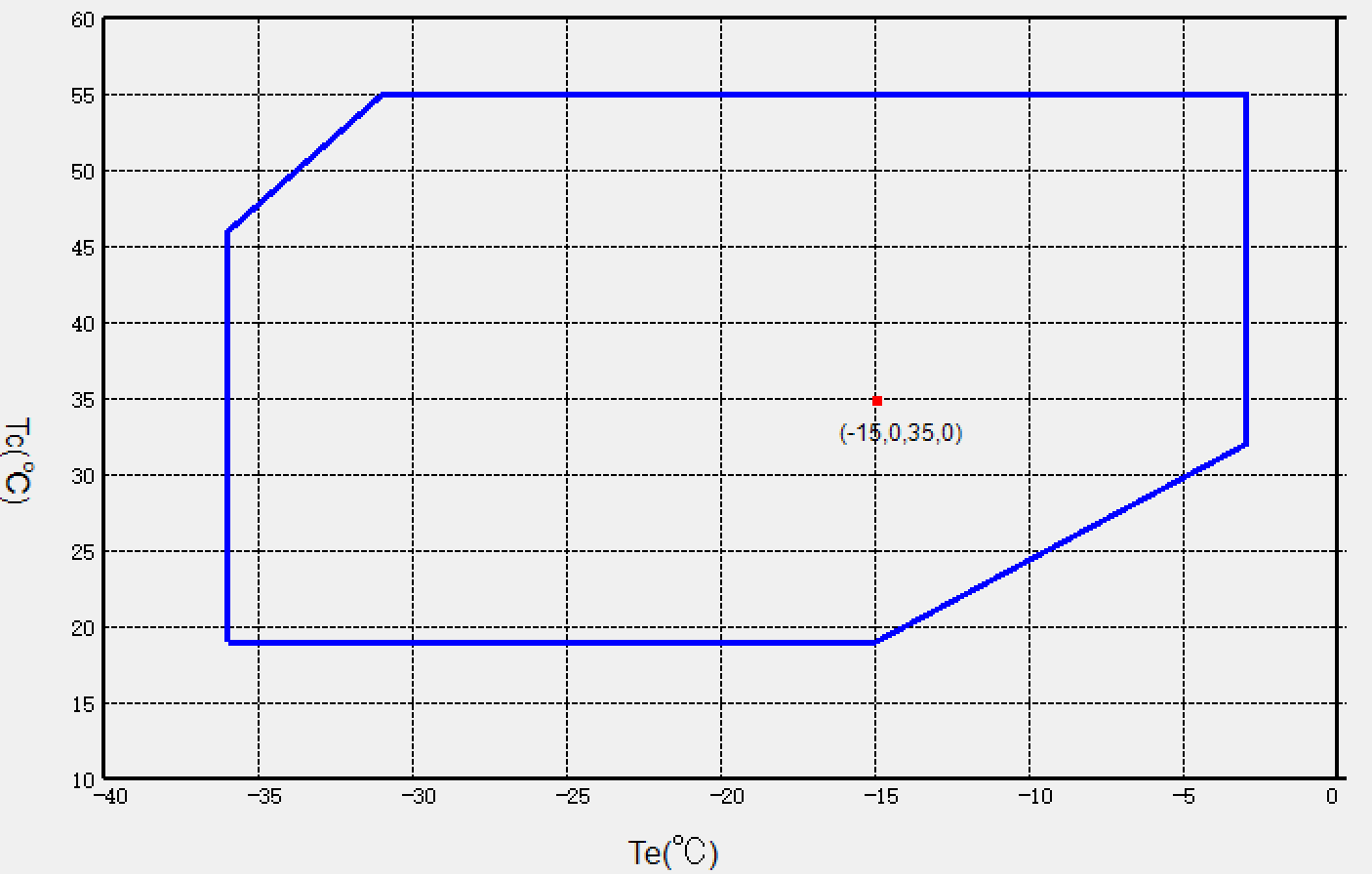

SRS High Temperature

This range with a larger motor is designed especially for medium to high temperature process cooling applications.

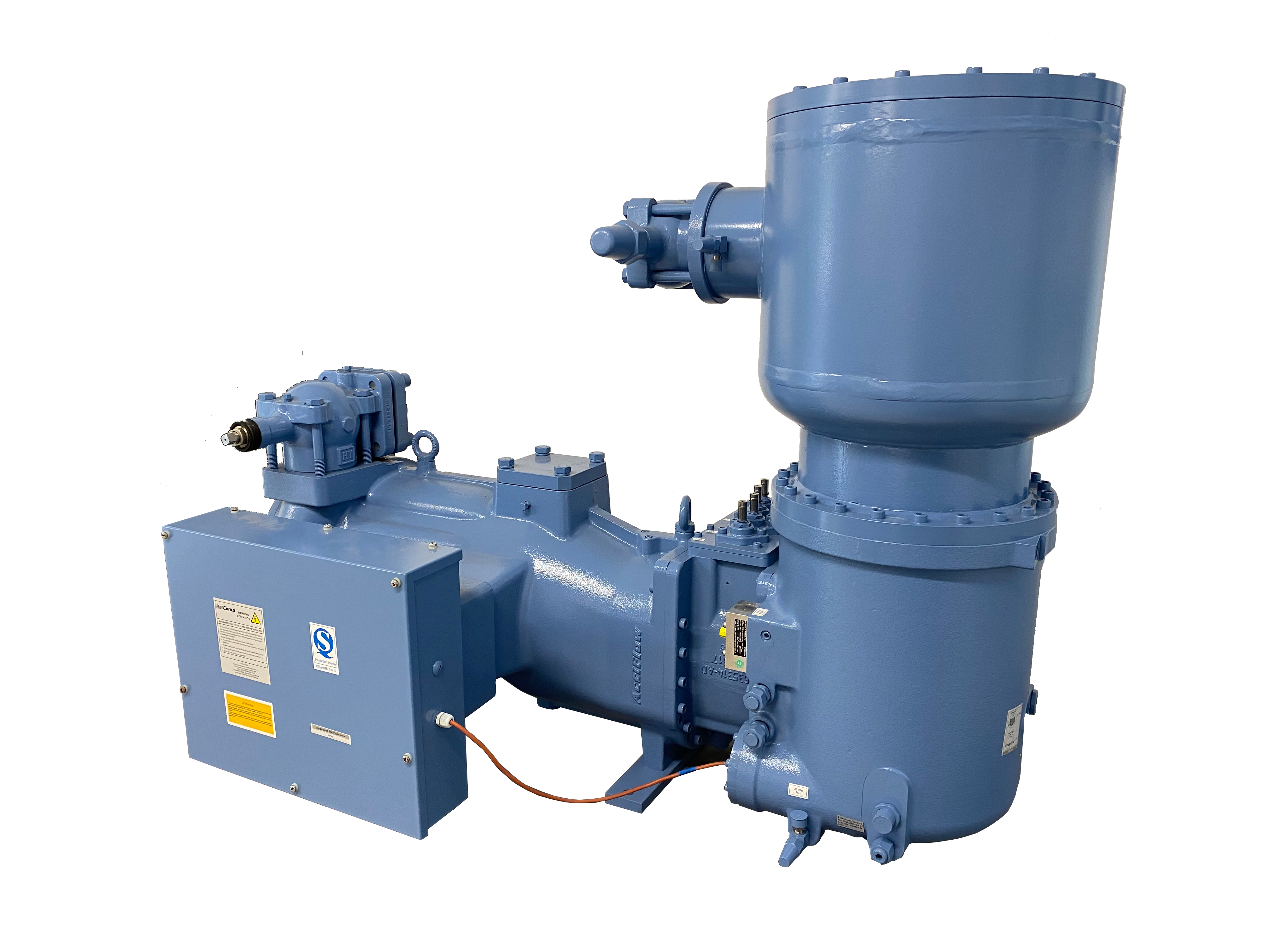

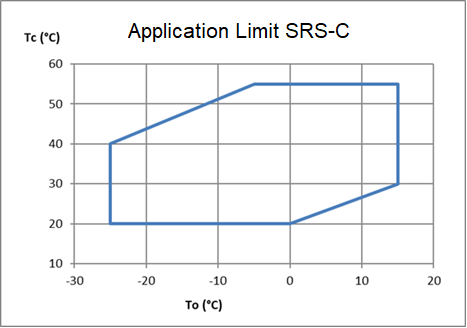

SRS-C Compressor

This most innovative compressor for Ammonia chiller applications is revolutionizing traditional design: the integrated oil separator leads to the most compact chillers possible reducing oil charge, pipes and connections thus reducing potential leakages and cost. Equipped with ActiFlow only the oil needed by the actual operation point is sent to the compressor thus improving efficiency of the whole system. The mechanical automatic Vi which needs no external input or control is ensuring continuously operation at its best point.