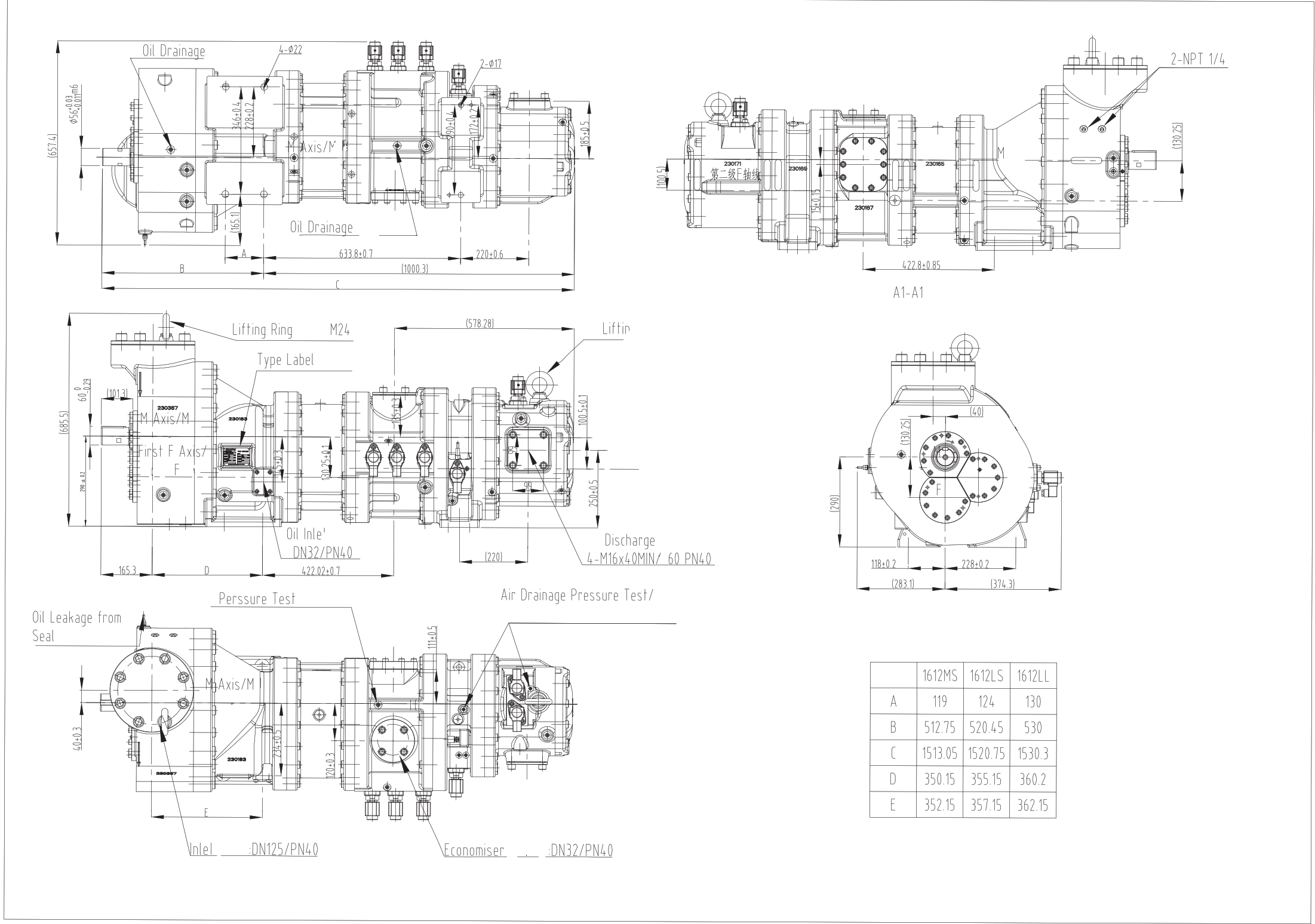

NO.SRM-1612

SRM-1612

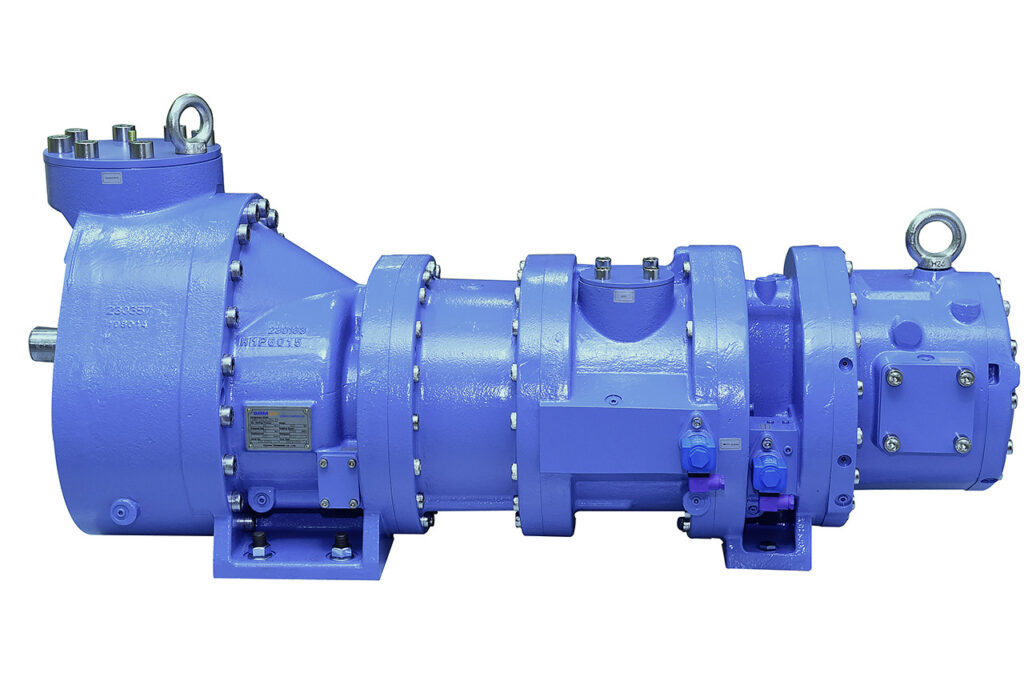

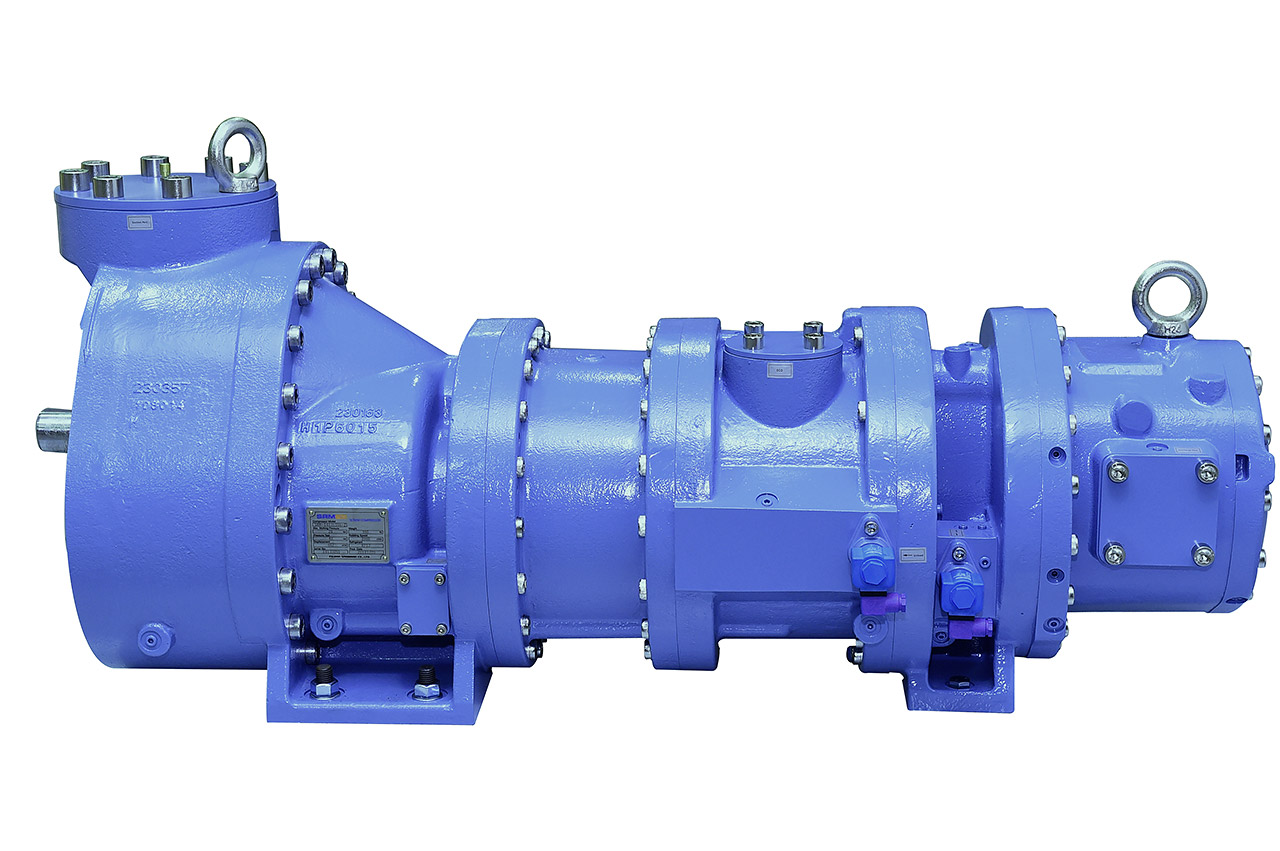

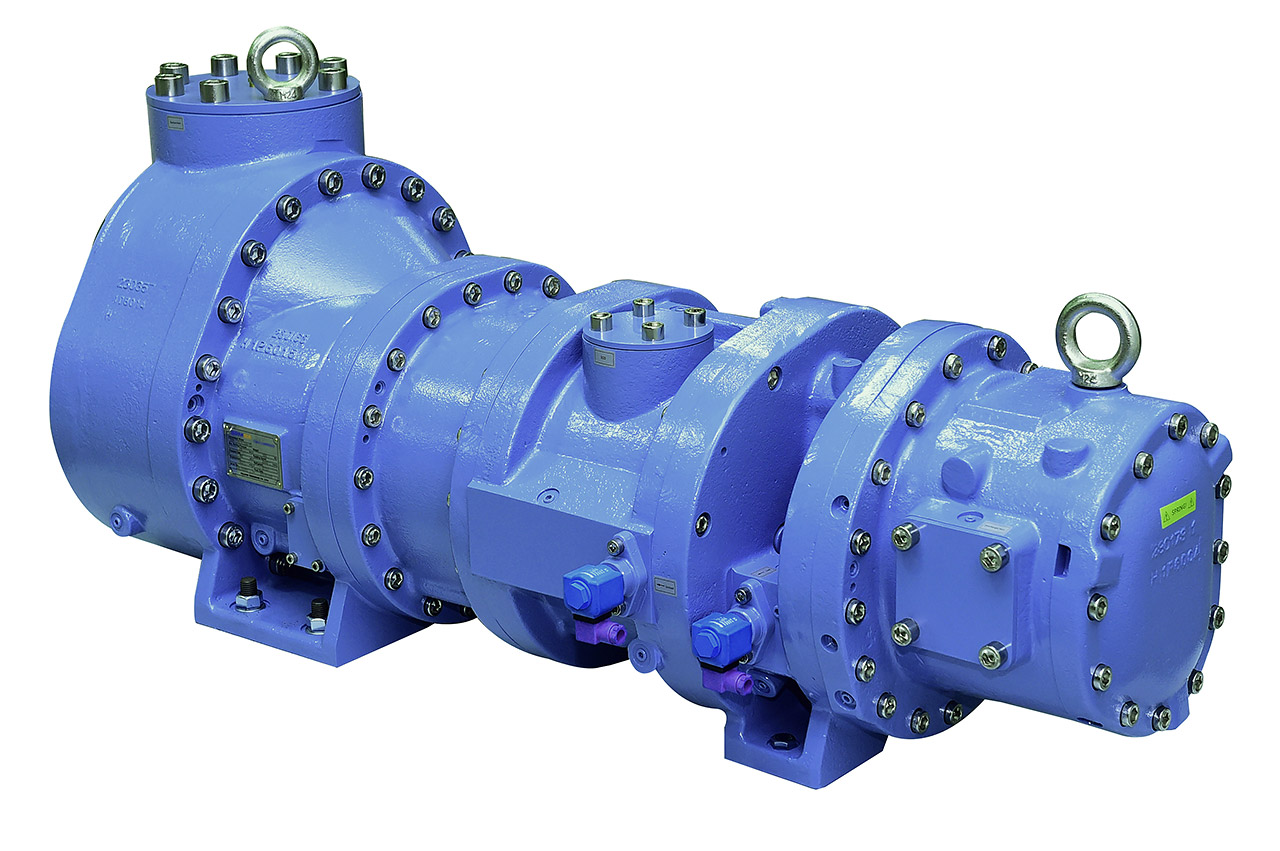

Open-type Double-stage Screw Compressor

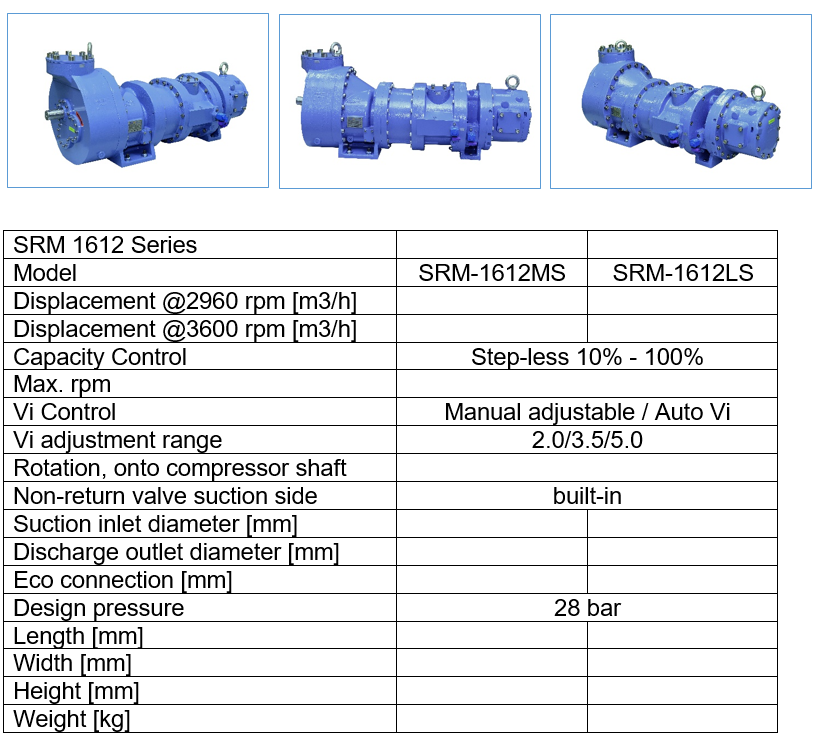

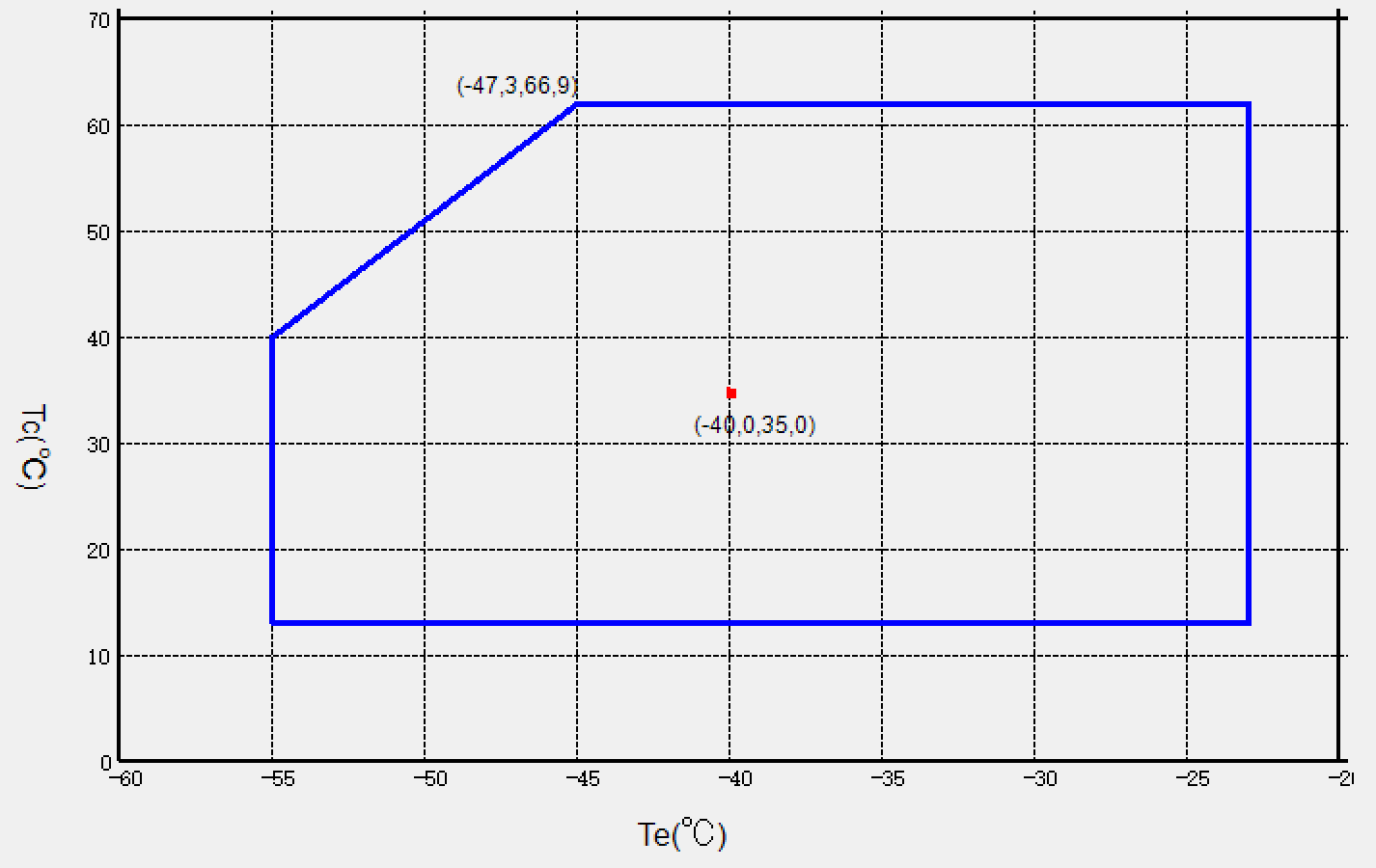

SRM open-type double-stage Screw Compressors include 4 series totaling 32 models with a displacement of 529 – 7723 m3/h @ 3600 rpm. The application window caters especially for low temperature applications, which traditionally were executed as booster systems. If no side-load for the high stage of the booster is needed, these double-stage compressors offer very compact and efficient solutions.

Whereas all major refrigerants can be used, our compressors are optimized for the natural and environment-friendly refrigerants such as Ammonia R717 and Hydrocarbons like R290, R600 and R1150.

The use of frequency inverters, step-less (10%-100%) mechanical capacity control and adjustable Vi ensure high efficient operation at varying load and temperature profiles, thus guaranteeing high SEER values.

The robust design and high degrees of obliquity >30° to withstand the rolling and pounding sea allow the use in marine applications2932

Features of SRM open-type double-stage screw compressor:

- “I”type patented profile, best lobe ratio of 5+7, high efficiency.

- Rotor is made of high- quality forged steel with micron- machining accuracy, high strength, high wear resistance, and long durability.

- The housing is made of high- strength ductile iron, design pressure: 2.8Mpa.

- Innovative shaft seal. The wear- resistant sealing surface is made of silicon carbide for high reliability.

- High- precision and wear- resistant roller bearings designed for a life span of 100.000 operating hours.

- The internal compression ratio Vi can be adjusted to the existing operating conditions either manually or automatically for highest efficiency, even under varying conditions.

- Stepless capacity control (10- 100%) by a mechanical slider.

- Integrated oil channels for secure lubrication of all critical spots within the compressor.