NO.SRM-26

SRM-26

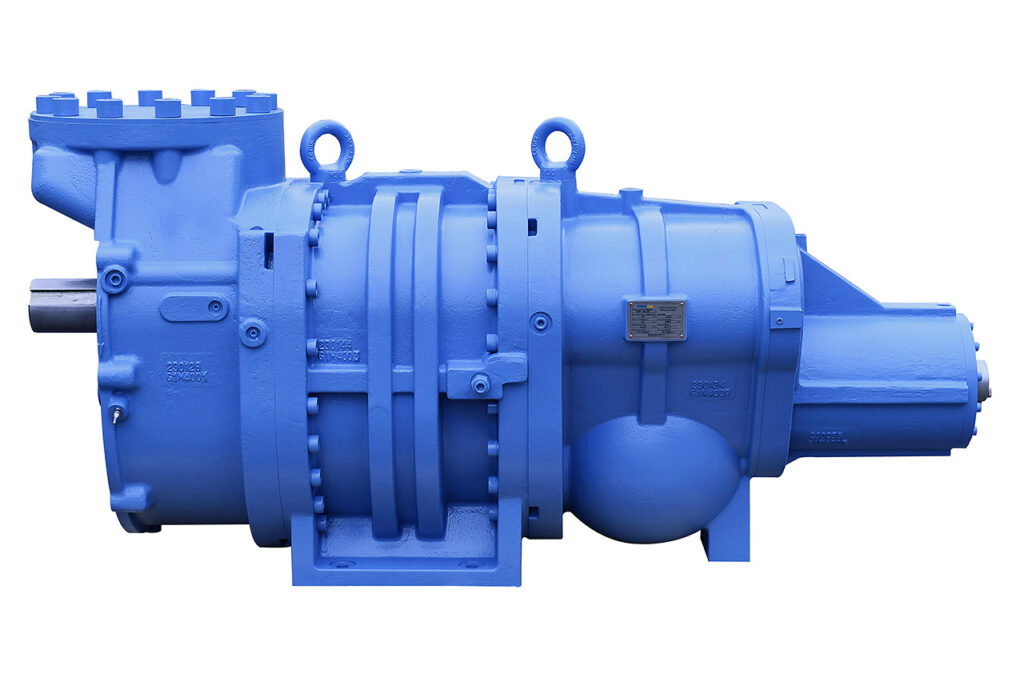

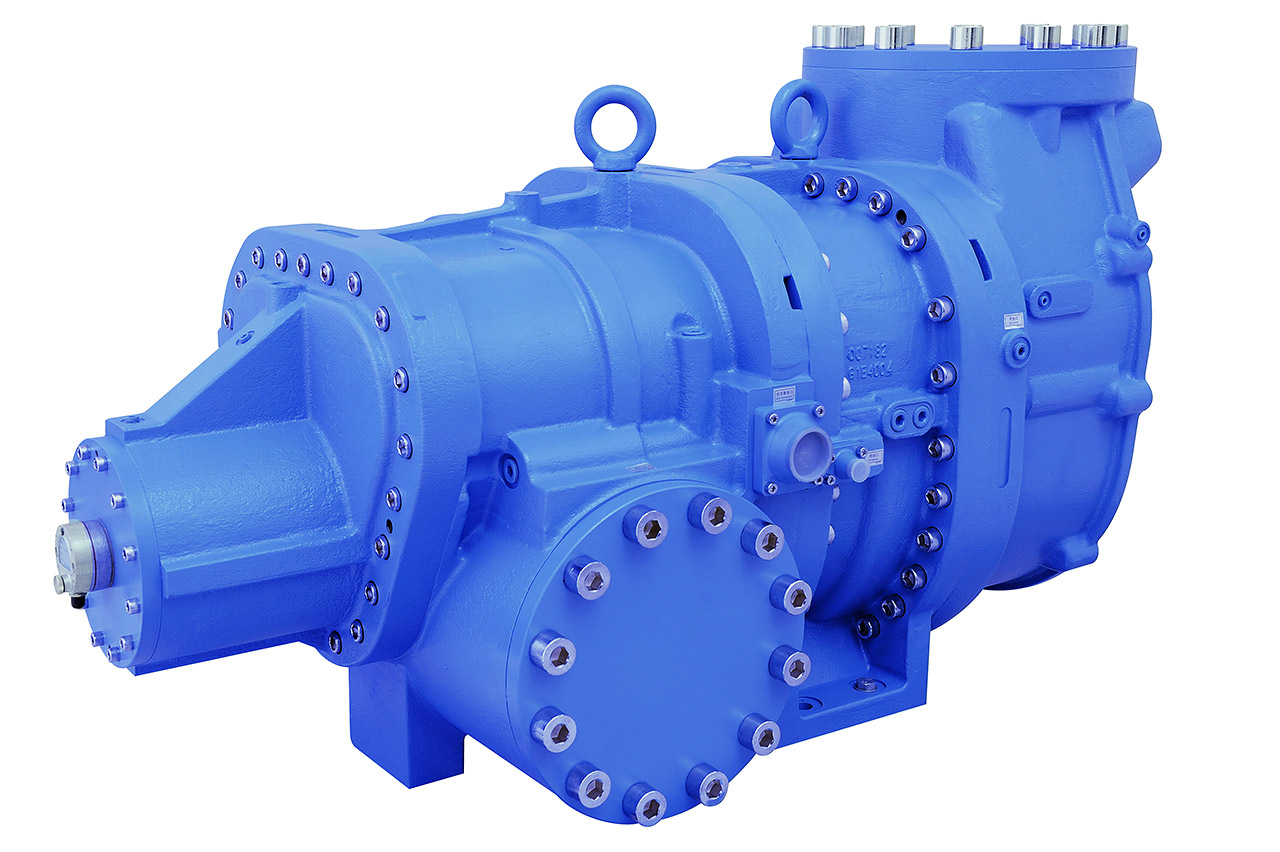

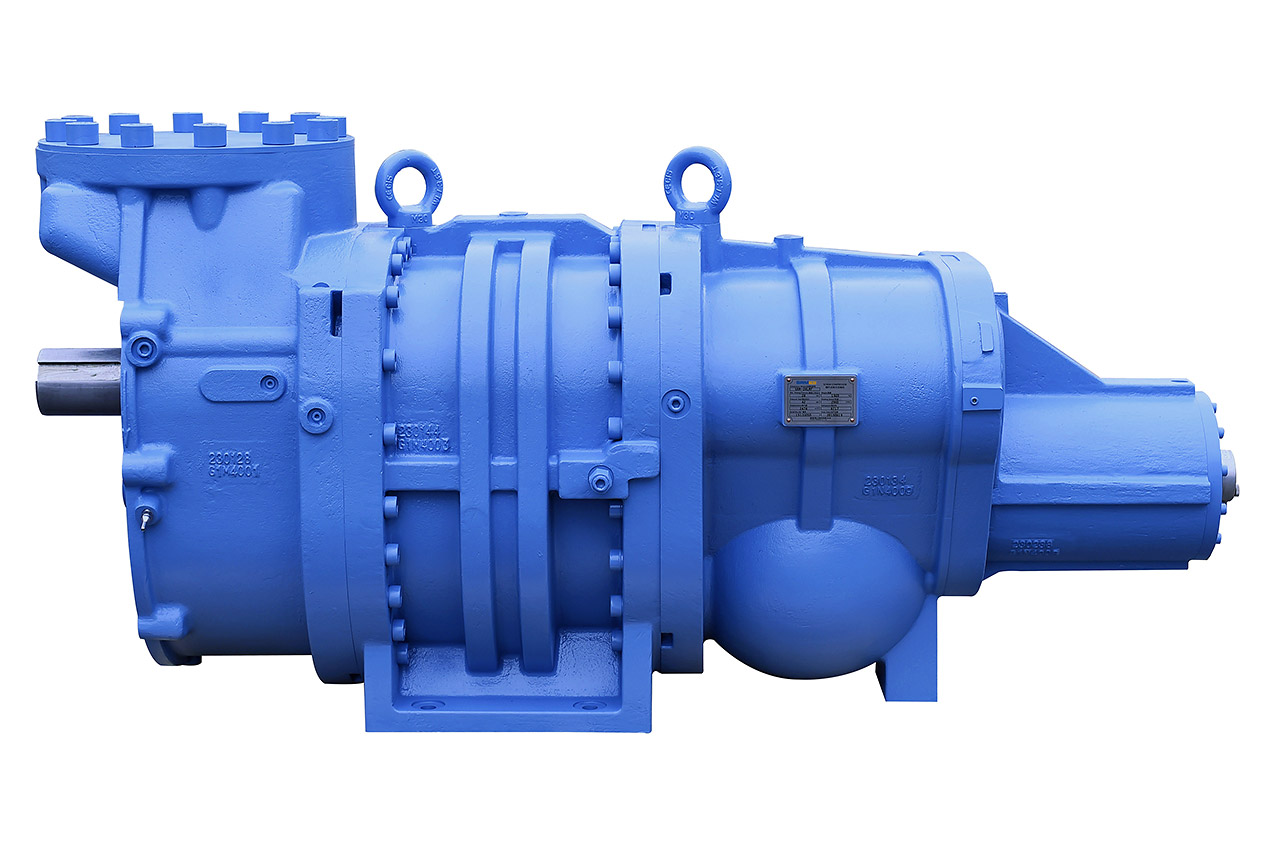

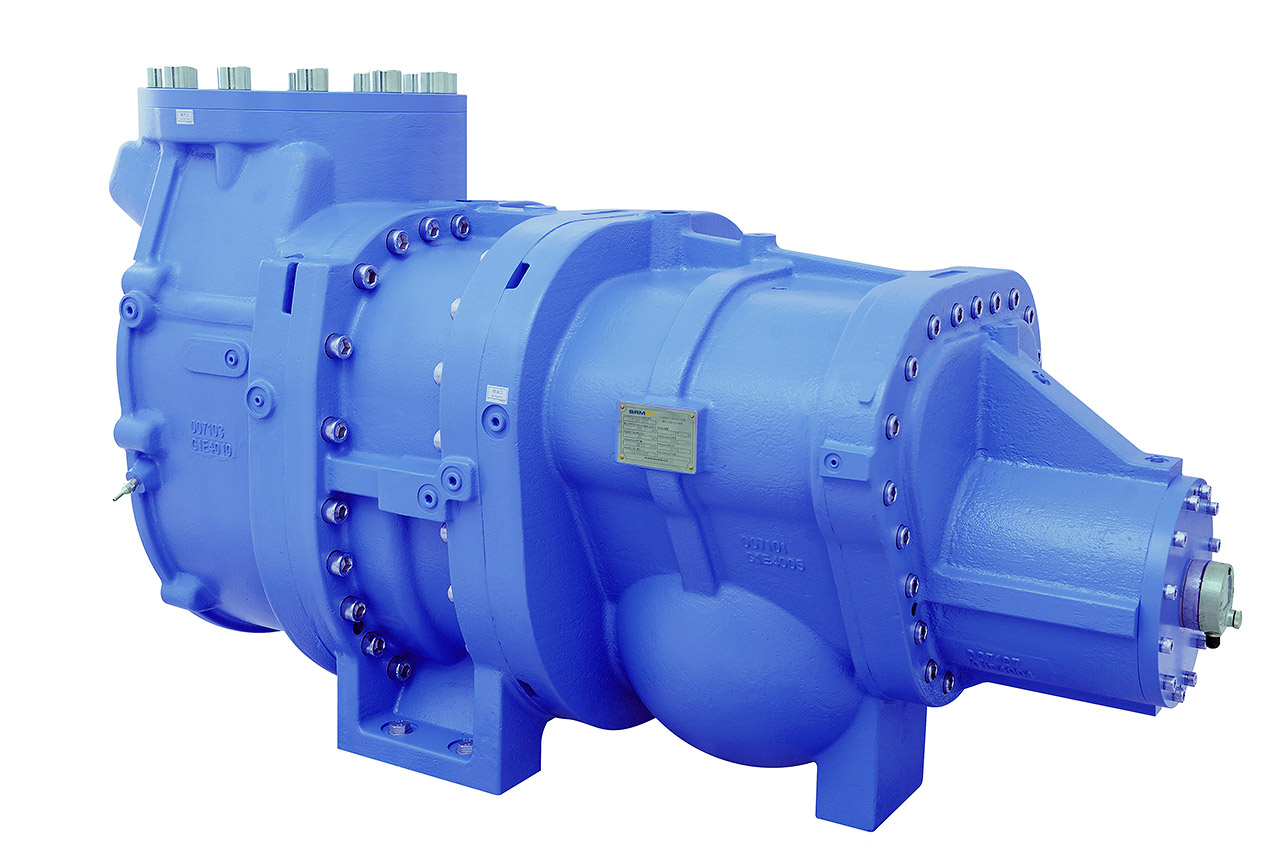

Open-type Single-stage Screw Compressor

SRM open-type single-stage Screw Compressors include 6 series totaling 19 models with a displacement of 265 – 10850 m3/h @ 2960 rpm. A large application window caters for a wide range of applications. Whereas all major refrigerants can be used, our compressors are optimized for the natural and environment-friendly refrigerants such as Ammonia R717 and Hydrocarbons like R290, R600 and R1150.

High rotor speeds of up to 6000 rpm for the smallest compressor allow the use of frequency inverters, step-less (10%- 100%) mechanical capacity control and adjustable Vi ensure high efficient operation at varying load and temperature profiles, thus guaranteeing high SEER values.

The robust design and high degrees of obliquity >30° to withstand the rolling and pounding sea allow the use in marine applications.

Features of SRM open-type single-stage screw compressor:

- “I”type patented profile, best lobe ratio of 5+7, high efficiency.

- Rotor is made of high- quality forged steel with micron- machining accuracy, high strength, high wear resistance, and long durability.

- The housing is made of high- strength ductile iron, design pressure: 2.8 Mpa.

- Innovative shaft seal. The wear- resistant sealing surface is made of silicon carbide for high reliability.

- High- precision and wear- resistant roller bearings designed for a life span of 100.000 operating hours.

- The internal compression ratio Vi can be adjusted to the existing operating conditions either manually or automatically for highest efficiency, even under varying conditions.

- Stepless capacity control (10-100%) by a mechanical slider.

- Integrated oil channels for secure lubrication of all critical spots within the compressor.

Dairy Industry screw compressor package for process cooling

Dairy Industry screw compressor package for process cooling

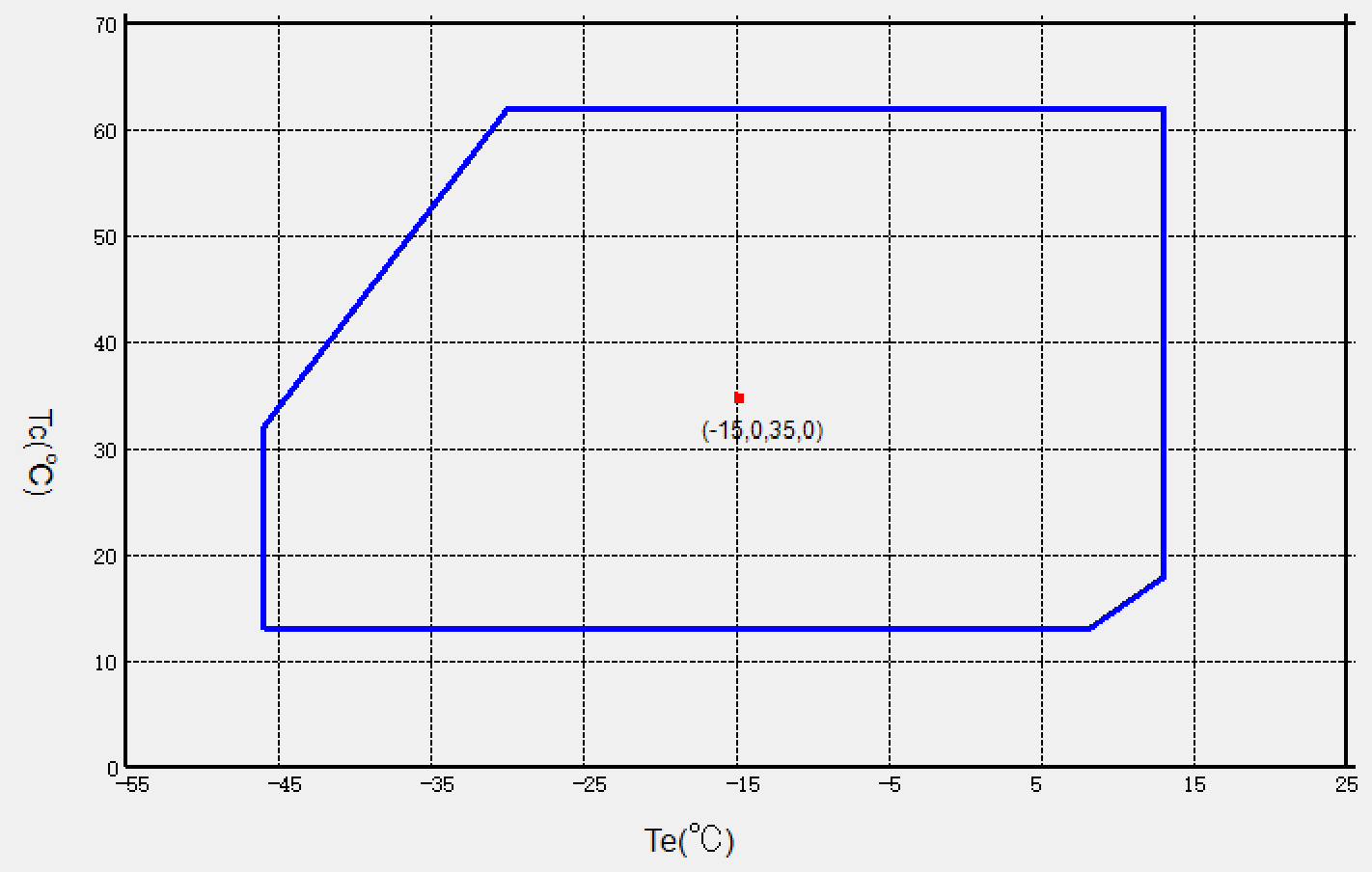

The recent upgrade of the cooling facility of dairy company ESNELAT in the Basque region of Spain was based on SRMTec technology. The SRM26M open-drive compressor package was replacing an old compressor system which was causing increasingly high maintenance and service cost.

The new system can pro-actively adapt to the seasonal fluctuation of the ambient conditions to bring condensing and evaporation temperatures in line to achieve best performance and energy savings.

Generously dimensioned suction and double oil filters plus strong piping and structures increase process security for the project owner.

Technical data:

Cooling capacity Qo: 1500 kW

Evaporation To: -9,5° C

Liquefaction Tc: 35° C

Installation: 10 / 2017

Food Processing with Booster System of SRM

Food Processing with Booster System of SRM

The recent extension of the current piston compressor cooling facility of

Salmon company VEGA in Northern Germany was based on SRMTec technology.

The combination of SRM20M and SRM26M booster open-drive compressor packages are engineered and installed by ARCTOS Industriekälte AG.

The SRMTec combination of 1 x SRM26M and 1 x SRM20M compressor-pack as booster system assures a maximum of flexibility with several side loads and is ready for future extensions.

The low stage booster pack provides 500kW at (-)40 deg C which is condensed against the high-stage at

(-) 2 deg C.

The 500kW are allocated to spiral freezers, ice machine and cold storage whereas the high stage besides the condensing load is allocated to ante-rooms, process cooling and medium temperature cold storage.

Technical data:

Cooling capacity Qo: 500 kW L/T; 1230 kW M/T

Evaporation To: -40° C; -3°C

Condensing Tc: -2°C; +32° C

Commissioning: 08 /2018