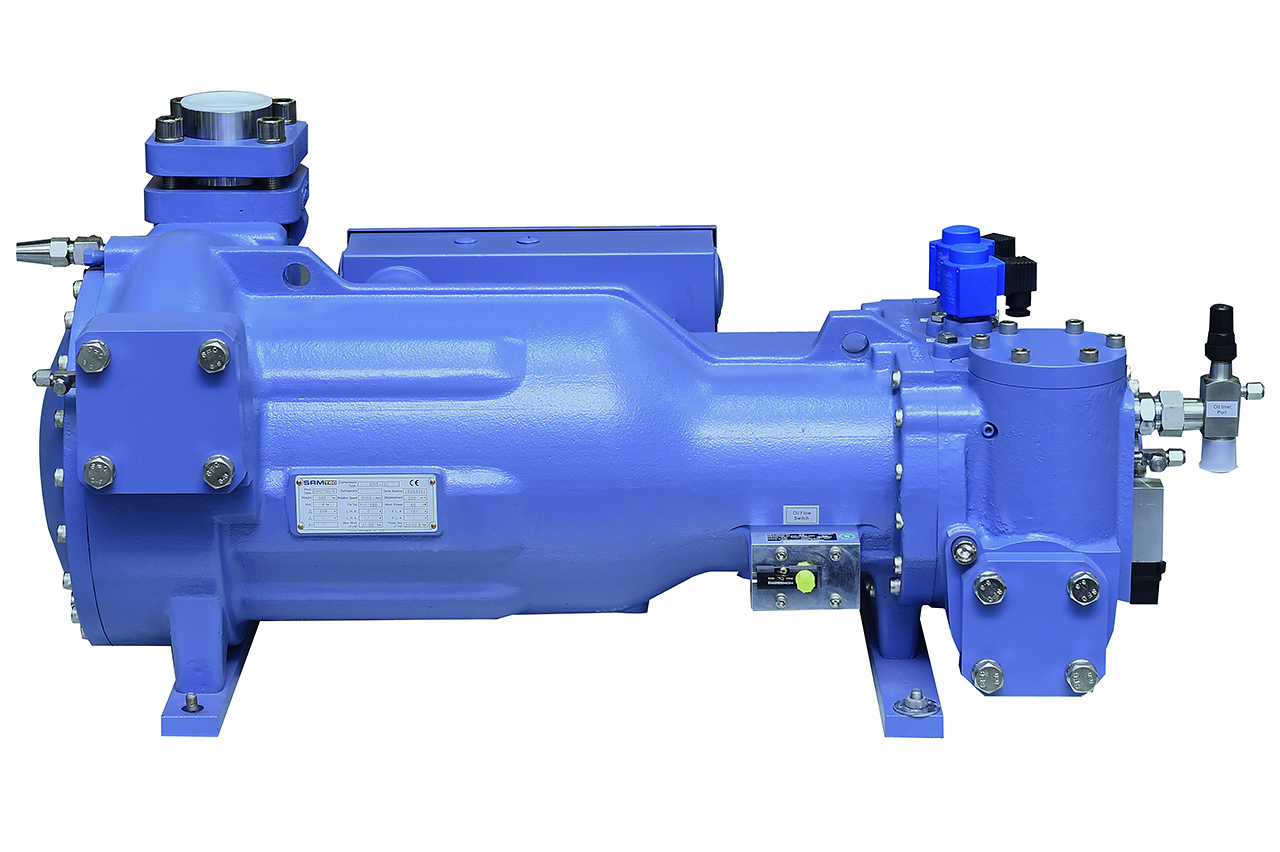

SRS-12

Semi-hermetic Single-stage Screw Compressor

SRS semi-hermetic single-stage Screw Compressors include 5 series totaling 14 models with a displacement of 84 – 500 m3/h @ 2960 rpm. A large application window caters for a wide range of applications. Whereas all major refrigerants can be used, our compressors are optimized for the natural and environment-friendly refrigerants such as Ammonia R717.

The semi-hermetic construction results in a permanent technical leak-proof solution without a shaft seal.

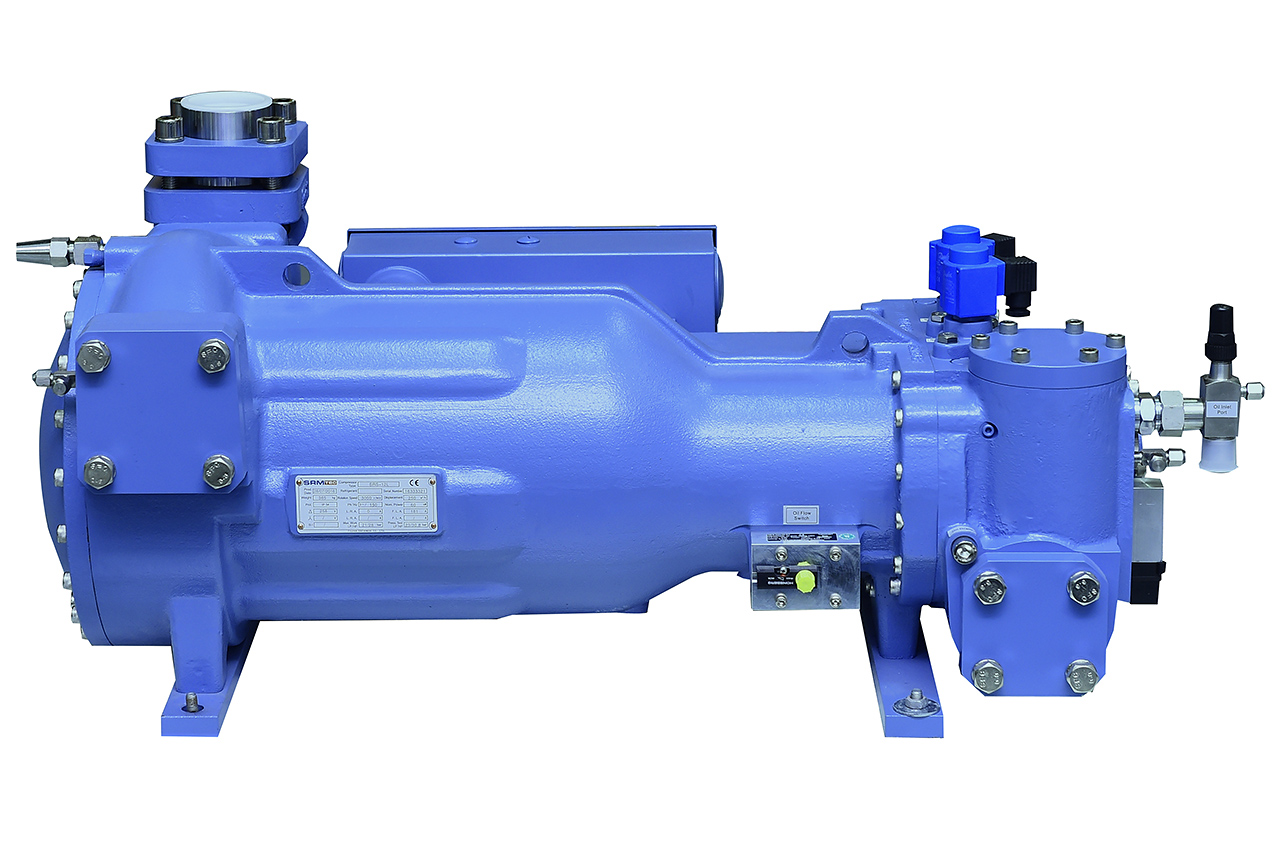

The use of frequency inverters, a permanent magnet synchronous motor and adjustable Vi ensure high efficient operation at varying load and temperature profiles, thus guaranteeing high SEER values.

Features of SRM open-type single-stage screw compressor:

- “I”type patented profile, best lobe ratio of 5+7, high efficiency.

- The aluminium windings of the PM motor are compatible with ammonia and need no extra protection which can get damaged or deteriorate over time.

- Rotor is made of high- quality forged steel with micron- machining accuracy, high strength, high wear resistance, and long durability.

- The housing is made of high- strength ductile iron, design pressure: 2.8 Mpa.

- High- precision and wear- resistant roller bearings designed for a life span of 80.000 operating hours.

- The internal compression ratio Vi can be adjusted to the existing operating conditions either manually or automatically for highest efficiency, even under varying conditions.

- Integrated oil channels for secure lubrication of all critical spots within the compressor.

- Suction and discharge ports can be swapped from left to right and turned 360° for easy mounting and connection in multiple compressor systems.

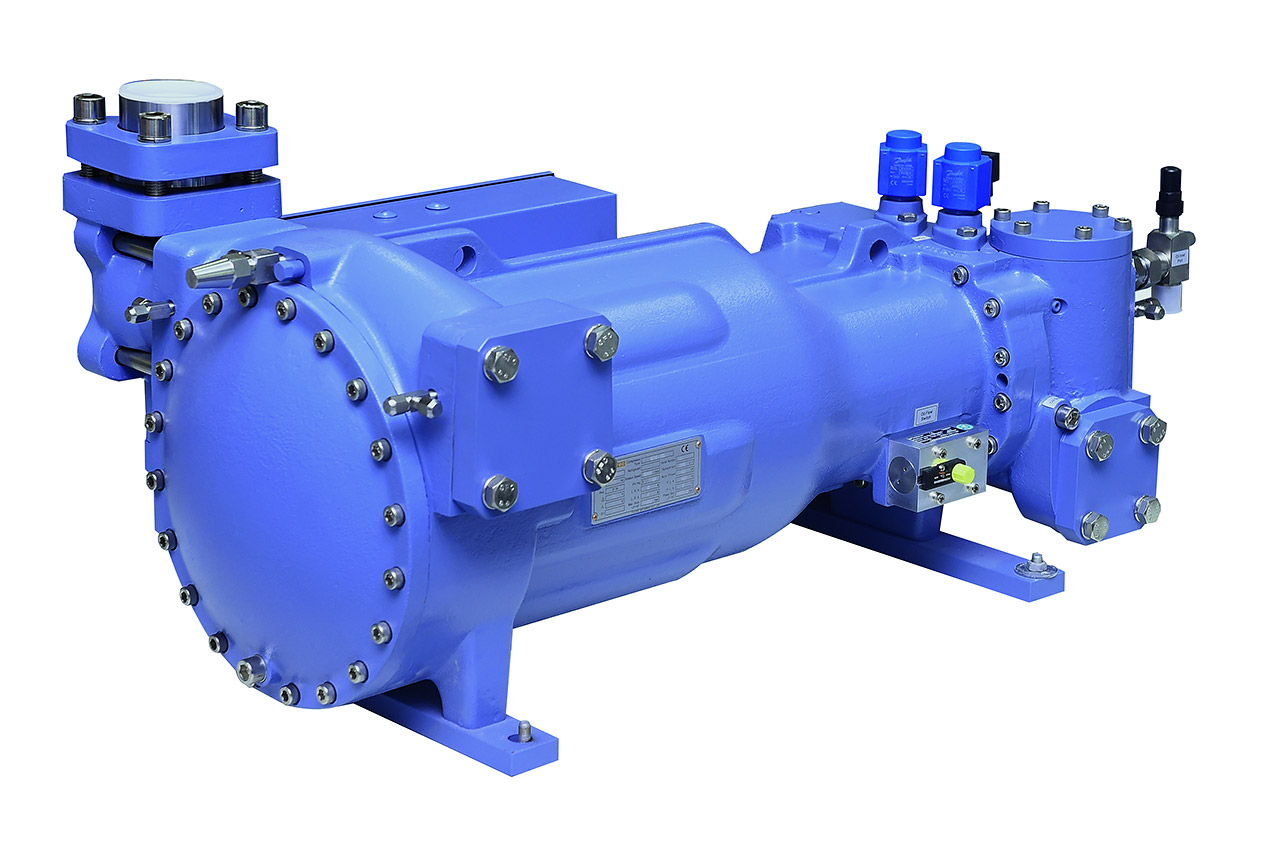

Process cooling by SRS Duopack

Process cooling by SRS Duopack

Vorarlberger Milch is a regional dairy cooperative of 600+ Austrian farmers with focus on sustainability of processes like short supply distances, non-genetically modified ingredients and care for the local culture, flora and fauna.

The production process needs to cater for hygiene, safety and economy but also has to be as gentle to nature as possible. The expansion of the cheese maturing rooms is realized by the natural refrigerant ammonia and by with semi-hermetic compressors which

are highly efficient and due to their design also leak-proof.

Contractor ENGIE Austria designed and built two duo-packs for small footprint and easy serviceability. Driven by inverters the capacity is always closely matched to the demand, thus being able to save energy.

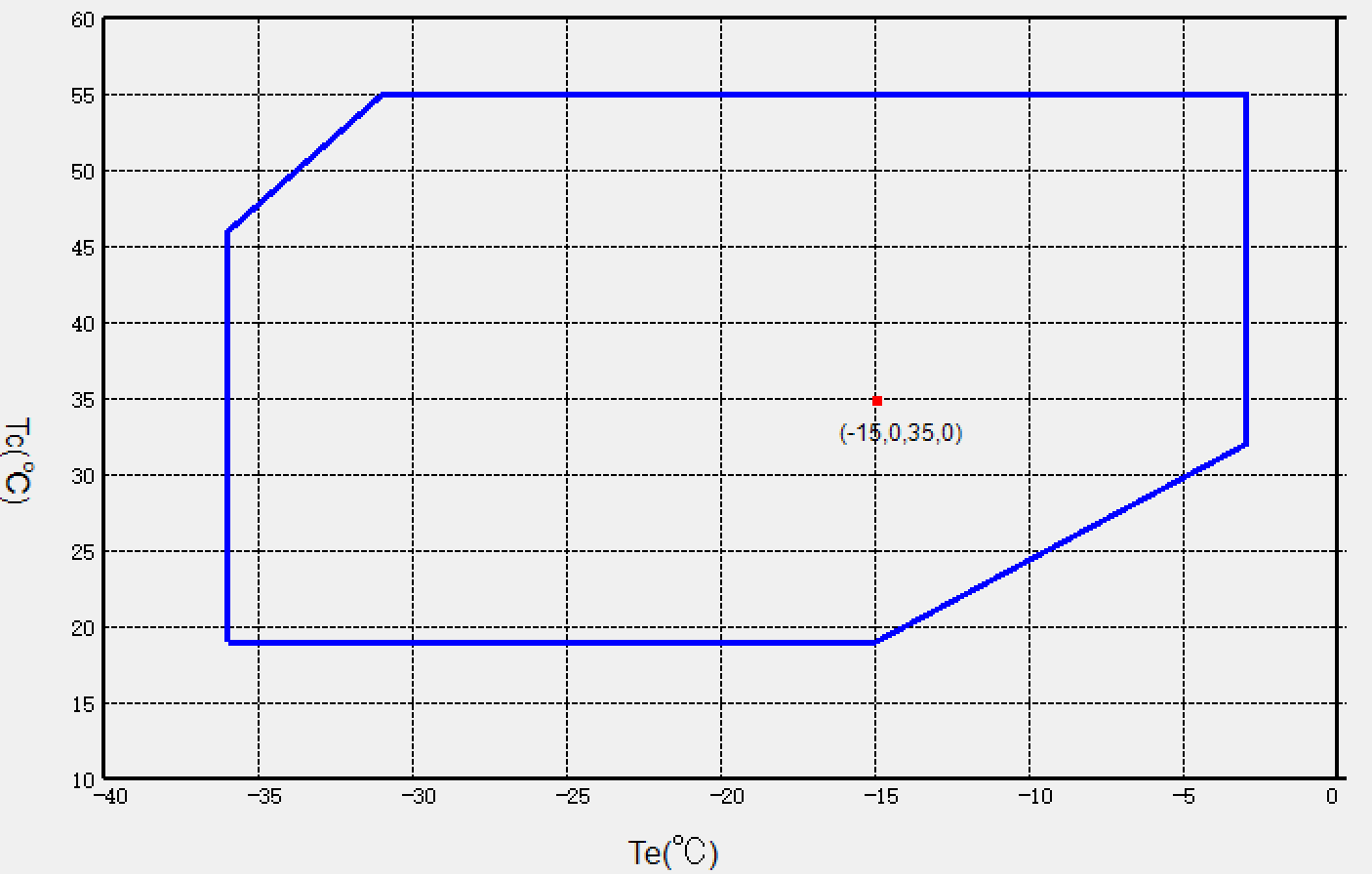

Technical data:

Cooling capacity Qo: 2 x 223 kW

Evaporation To: -8,5° C

Condensing Tc: +40,5° C

Commissioning: 03 /2019